Ducati Diavel Service Manual: Refitting the clutch transmission unit

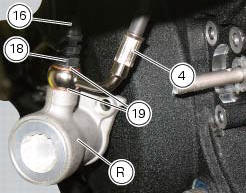

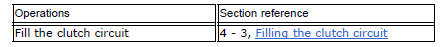

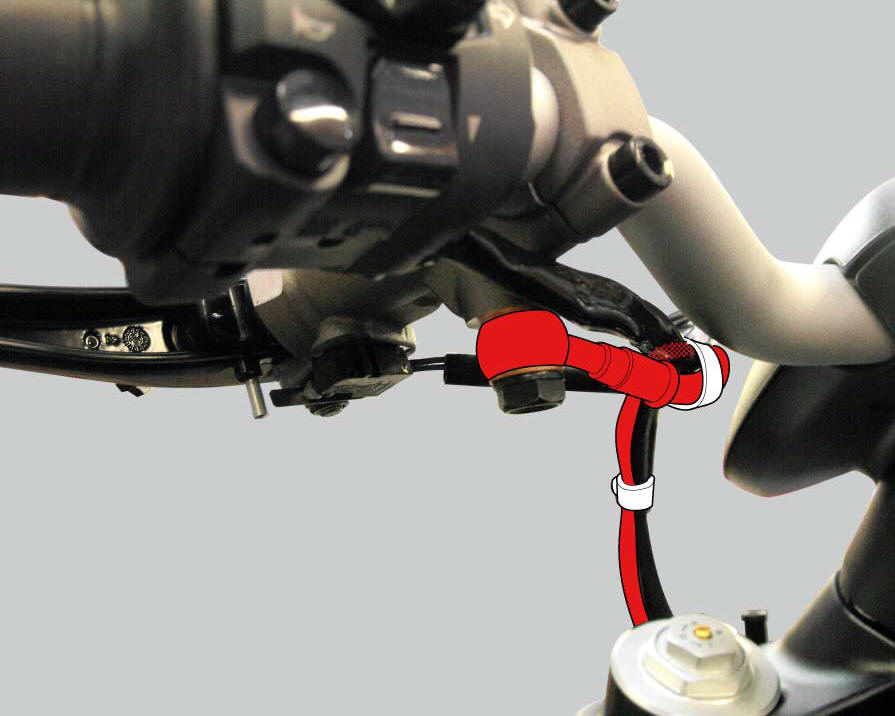

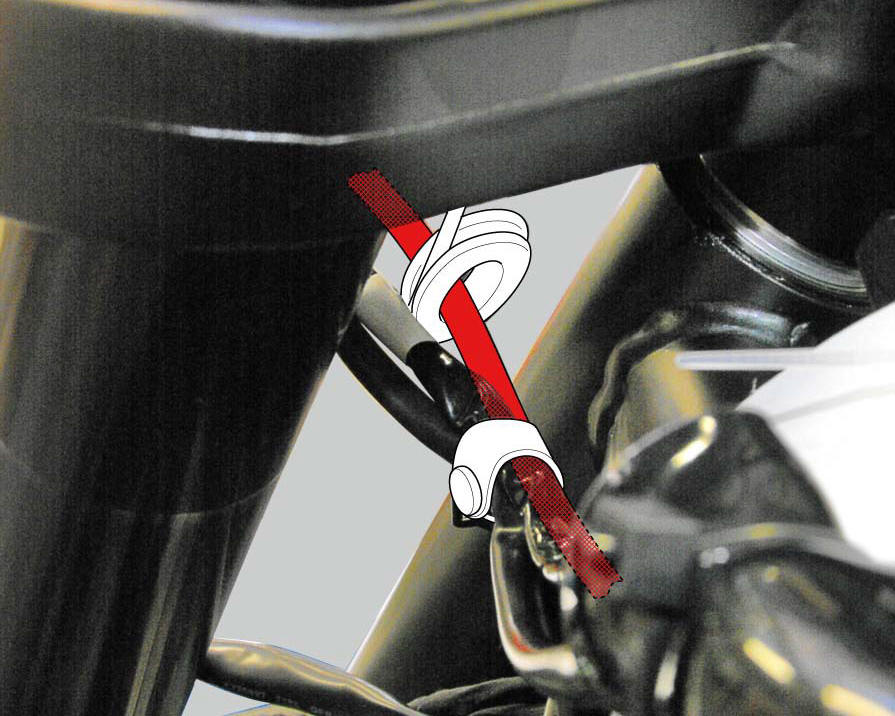

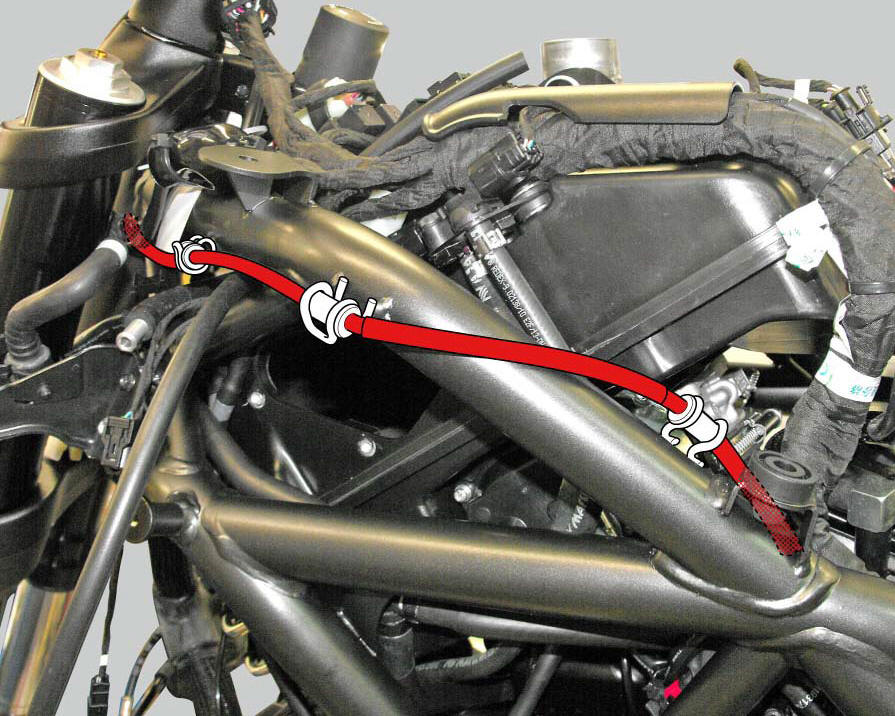

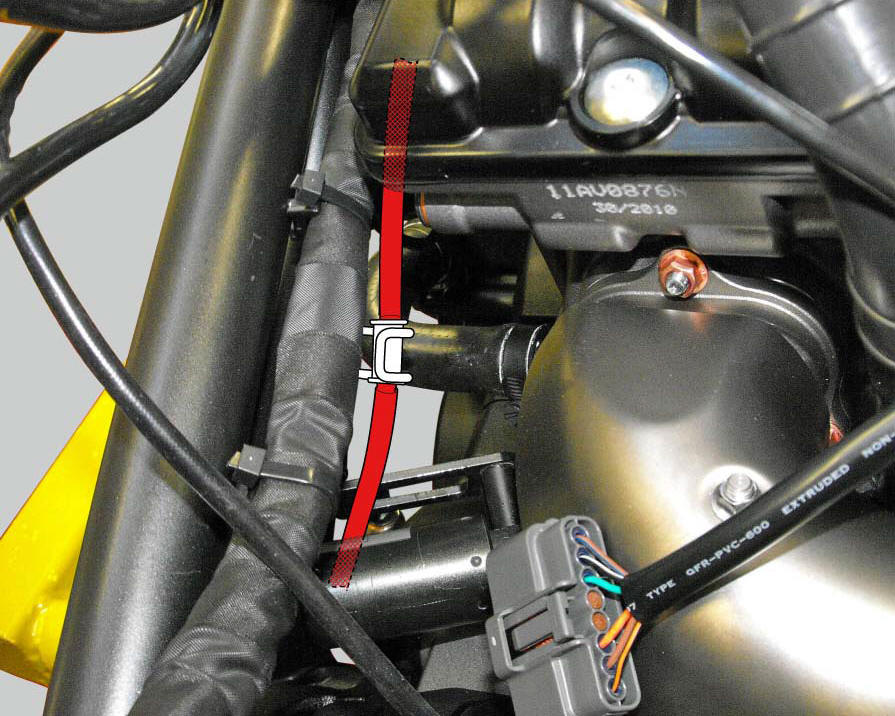

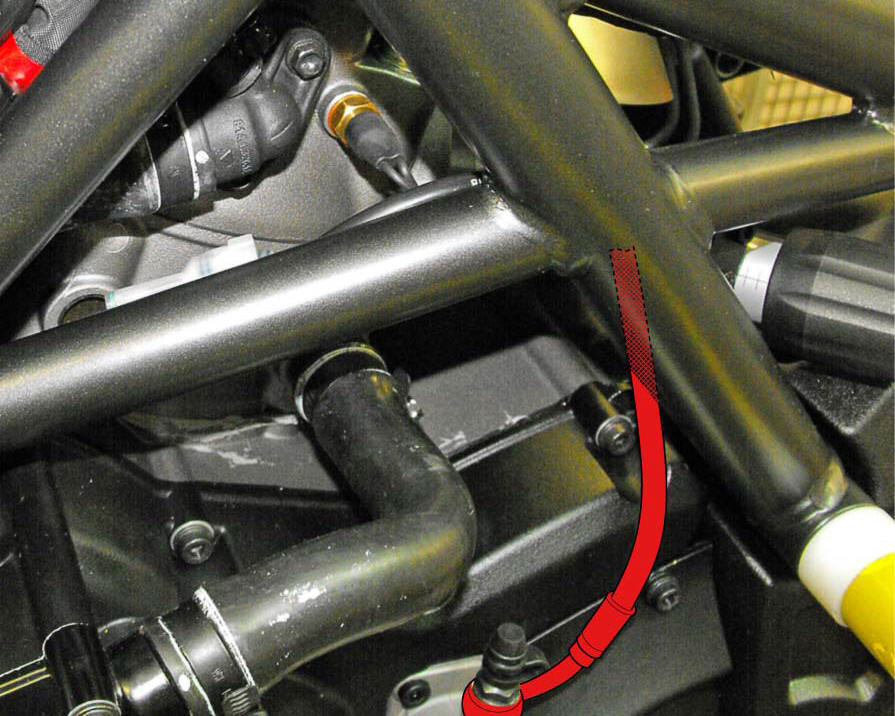

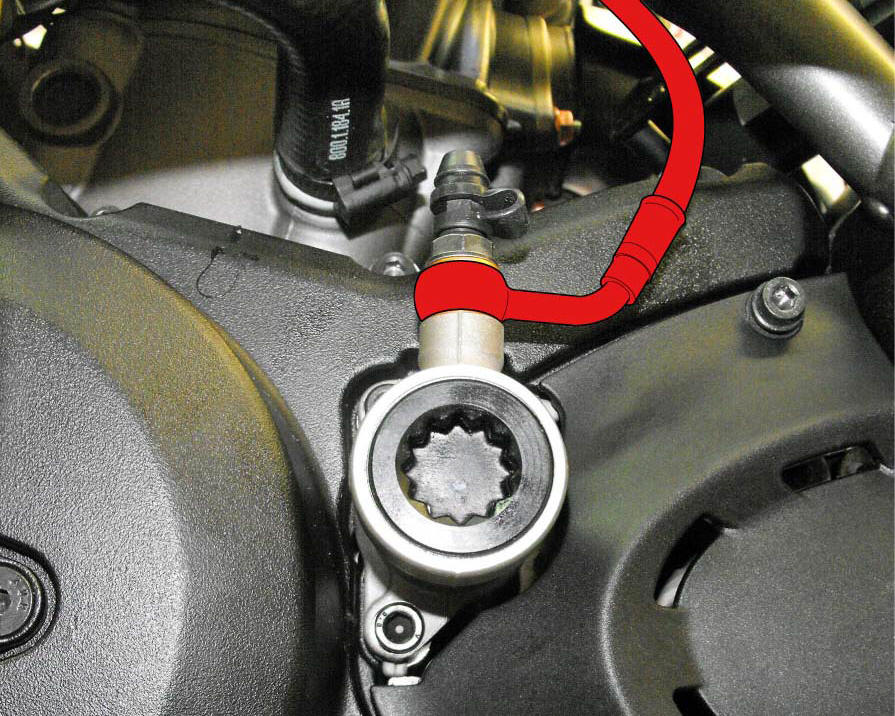

Position pipe (4) on the clutch slave cylinder (r).

Position the two seals (19) and tighten the screw (18) to a torque of 23 nm +/- 10% (sect. 3 - 3, Frame torque settings).

Refit the bleed valve (17) and the dust gaiter (16).

To position the pipe retaining clamps (4) refer to the table on the following page.

Push in the internal piston (a) to force out all the fluid from inside the cap.

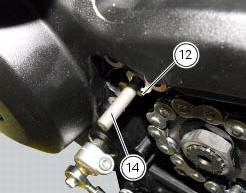

Make sure the anti-rotation pin (12) is fitted on the clutch pushrod (14).

Proceed as follows in case the anti-rotation pin (12) has been removed from the clutch pushrod (14).

Turn the clutch pushrod (14) until the axis of the anti-rotation pin (12) positioning hole is horizontal, as shown in the figure; grease the anti-rotation pin (12) and insert it into the clutch pushrod (14) hole.

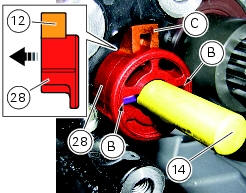

Insert the anti-rotation insert (28) fully home into the clutch pushrod (14) by matching the anti-rotation pin (12) with the slots (b) on the insert (28).

Note

The tab (c) of insert (28) must be inwards (casing side).

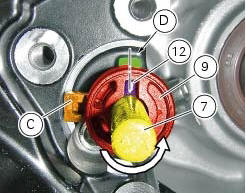

Turn the clutch pushrod (14) counter clockwise until the hole axis of the anti-rotation pin (12) is aligned with the centreline of the casing cover machined surface (d), as shown in the figure.

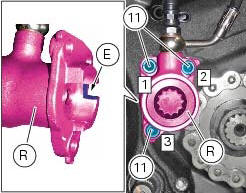

Insert the clutch actuator (r) into the pushrod (14) and bring it fully home on the anti-rotation insert (28).

Note

Upon insertion of the clutch actuator (r), make sure that the tab (c) of insert (28) matches with the actuator slot (e).

Fix the clutch actuator (r) by starting the screws (11).

Note

To bring the clutch slave cylinder (6) internal surface near the casing cover as uniformly as possible, screw and tighten the screws (11) alternatively.

Tighten the screws (11) to a torque of 10 nm +/- 10% (sect. 3 - 3, Frame torque settings), by following the sequence 1 - 2 - 3 - 1.

Positioning of the clutch hose

Removal of the clutch transmission unit

Removal of the clutch transmission unit

Warning

The manufacturer of the clutch transmission unit (15) advises

against servicing of its internal parts due to the safetycritical

nature of this component.

Incorrect overhaul of these cri ...

Hands free

Hands free

Hands free

Special screw

Plug

Electric fuel plug

Button

Spring

Frame

Elastic pin

Spare parts catalogue

Diavel abs handlebar and controls

Diavel carbon

abs

handlebar and con ...

Other materials:

Recovery procedure in the event of electric steering lock fault

If any fault occurs during activation of the electric steering lock: for

example, if the pin jams, if the handlebar is moved

while the pin is deployed or if there is excessive strain on the electric pin

actuator motor, the electric steering lock is

automatically disengaged and the hands free s ...

Indicator speed avg - average speed

This function shows the average speed of the motorcycle.

The calculation is made considering the distance and time

travelled since the last trip 1 reset. When trip 1 is reset, the

value is set to zero and the first available value is shown on

the display 10 seconds after the reset. Dashes &quo ...

Disassembly of the rear brake control

The brake master cylinder is supplied only as a complete unit; internal

components cannot be replaced.

To disassemble the master cylinder's outer parts, follow the indications given

in the exploded view at the beginning of this

section.

If the bush (10) inside the brake pedal (6) needs to ...