Ducati Diavel Service Manual: Refitting the cylinder head assemblies

Warning

To prevent oil leaks past the contact area between cylinders and crankcase, each time the head is removed, cylinder and piston must be removed as well to clean the mating faces of crankcase and cylinder and restore the spoiled gaskets and o-rings and apply again liquid sealant (sect. 9 - 5, Refitting the cylinder/piston assembly).

Before fitting the head, check that the seal is fitted on the mating surface between head and cylinder (sect. 9 - 5, Refitting the cylinder/piston assembly).

Note

When fitting the gasket, side (e) with the stamped code must be in contact with the cylinder head.

Lower the cylinder head carefully over the studs. Take care not to damage the threads.

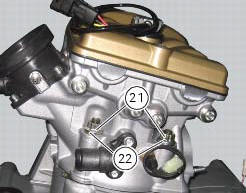

Fit the special washers (22) and nuts (21) onto the cylinder head studs.

Tighten the nuts (21) on the stud bolts evenly and gradually in a crosswise pattern using tool 88713.2676 In conjunction with a torque wrench.

Temporary tighten the nuts (21) to a torque of 20 nm; pre-tightening to a torque of 40 nm (min. 38 Nm - max. 48 Nm); one tightening to a torque of 60 nm (min. 57 Nm - max. 63 Nm) (sect. 3 - 3, Engine torque settings).

Reassembly of the cylinder head

Reassembly of the cylinder head

The exhaust side can be identified by the three threaded holes on the flange.

The intake side can be identified by the presence of four threaded holes on

the flange.

All the photos in this ...

Cylinder/piston assemblies

Cylinder/piston assemblies

Piston

Gudgeon pin circlip

Gudgeon pin

Set of piston rings

Cylinder-crankcase gasket

Water pump outlet union

Hose clip

Horizontal cylinder coolant inlet hose

Vertical cylinder c ...

Other materials:

Stop light not working

Fault codes

Dds: stop light diagnosis -> stop light error (generic stop light malfunction

indication).

Dashboard: the error "stop light" is shown on the service display. The eobd

warning light activates.

Wiring diagram

Db dashboard connection, bbs bbs unit connection, a front brake ...

Refitting the tail light

Fit the spacers with collar (3) into the rear vibration dampers (2) located

on the gloves compartment (23).

Note

Two spacers (3) must be inserted inside and outside on the right side and

two spacers (3) must be inserted inside and

outside on the left side.

Insert the split vibration damp ...

Radiator fan relay

Introduction

The radiator fans are powered via a specific relay, which is enabled by the

engine control unit.

Component assembling position

A injection relay; b etv relay (throttle valve actuator motor), c radiator

fan relay, d engine control unit.

Location of right hand fan connecti ...