Ducati Diavel Service Manual: Refitting the cylinder/piston assembly

If new units are used, it is necessary to couple the cylinders and pistons of the same selection (see paragraph "overhaul Of the cylinder barrel/piston components" of this section).

If the pistons have been separated from their cylinders, before reassembling these components, position the piston ring gaps at 120 from one another (the markings must always face the piston crown).

Note

For better sealing the piston ring gaps should be positioned at 180 intervals.

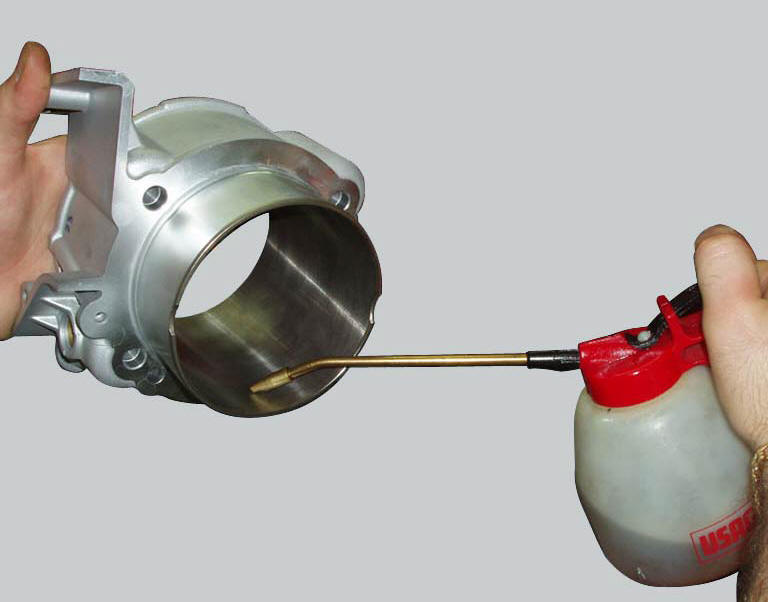

Use a universal tool to carefully insert the piston into the cylinder (first lubricate the inside of the cylinder with engine oil). Position the cylinder with the smallest valve recess is on the side of the exhaust port.

Remove

Remove any deposits and degrease the contact surfaces of the crankcase half and the cylinders.

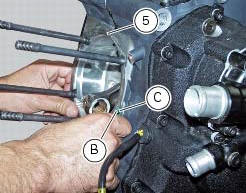

Check for the presence of the cylinders centring dowels (b) and the o-ring (c) on the base.

Apply sealant to the gasket (5) then locate the gasket on the crankcase.

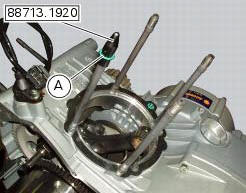

Using the cap 88713.1920, Fit the o-rings (a) on each stud bolt and guide them into their seats in the crankcase.

Bring the connecting rod small end close to tdc and slide the barrel-piston assembly (1-10) onto the crankcase studs.

Push the connecting rod small end into the piston close to the gudgeon pin (3) bore. Lubricate and insert the gudgeon Pin.

The gudgeon pin (3) must slide smoothly in the connecting rod small end bush and in the piston (1).

Close the crankcase opening with a cloth to prevent foreign objects from falling inside and then fit the retainer ring (2) as shown in the figure.

Important

Always fit new circlips (2) on reassembly.

Push the cylinder barrel (10) down until it seats against the crankcase.

Refit the bushes (12).

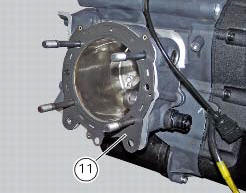

Fit the cylinder head gasket (11) over the studs. The side marked with the part number must be facing the cylinder head.

Note

The shape of the gasket prevents incorrect fitting, provided that the coolant flow holes are aligned with those on the cylinder.

Repeat the procedure for the other cylinder and refit the cylinder heads (sect. 9 - 4.5, Refitting the cylinder head assemblies).

In case they have not been assembled, apply prescribed threadlocker to unions (6) and tighten them to a torque of 25 nm (min. 23 Nm - max. 27 Nm) (sect. 3 - 3, Engine torque settings).

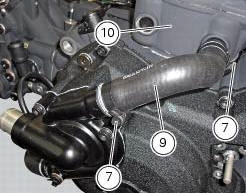

Fit the tubes (8) and (9) and tighten clamps (7) to a torque of 2.5 Nm (min. 2 Nm - max. 3 Nm) (sect. 3 - 3, Engine torque settings).

Overhaul of the cylinder barrel/piston components

Overhaul of the cylinder barrel/piston components

Overhauling the cylinder

Check that the walls of the cylinder bore are perfectly smooth. Measure the

cylinder bore diameter at 50 mm from the top

face and determine the size class to which it belo ...

Clutch assembly

Clutch assembly

...

Other materials:

Refitting the throttle twistgrip

Lubricate the ends of the throttle grip cables (10) and the twistgrip race

with the recommended grease.

The closing cable (10) features a writing on the yellow tube, whereas the

opening one (10) features such writing on the

white tube.

To refit the throttle control components, proceed i ...

Lap activation/deactivation function (lap time)

This function activates and deactivates the lap function (lap time).

To access the function it is necessary to view the ""setting" menu", using

buttons (1) "s" or (2) "t" select the "lap"

function and press the reset button (3) to enter the following page.

Function state is highlighted on t ...

Vehicle speed indicator

this function displays vehicle speed (km/h or mph

depending on the set measurement system).

the instrument panel receives information about the actual

speed and displays the number increased by 5%.

maximum speed displayed is 299 km/h (186 mph).

over 299 km/h (186 mph) a series of dashes w ...