Ducati Diavel Service Manual: Refitting the expansion tank

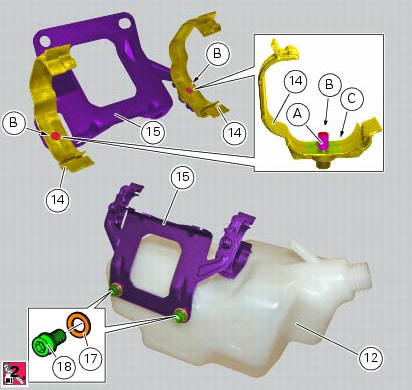

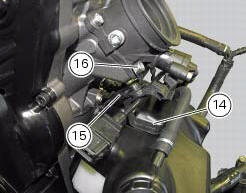

If the support (15) has been removed, place the hose clamps (14) on the bracket (15) orienting them as indicated.

Fully press the pins (a) to block the clamps (14) until pins surfaces (b) are at the same level of the clamps (14) surfaces.

Apply recommended threadlocker to the thread of the screws (18) and insert them into washers (17).

Place the bracket (15), as indicated, on the expansion reservoir (12) and tighten the screws (18) to a torque of 5 nm +/- 10% (sect. 3 - 3, Frame torque settings).

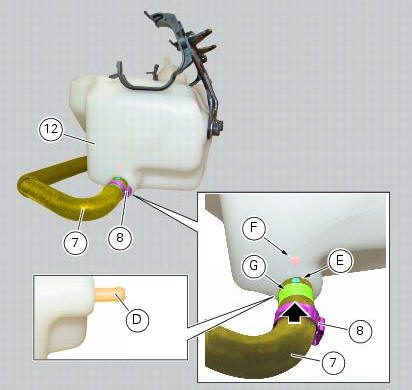

Fit the clip (8) on the hose (7).

Insert completely the hose (7) into the lower fitting (d) of the expansion reservoir (12), by orienting it so as the reference (e) of the hose matches with the arrow in relief (f) on the expansion reservoir.

Note

In case of difficulties during insertion of the hose (7) into the fitting (d) it is recommended to apply lubricant suitable for rubber to the fitting.

Orient the clamp (8) as indicated and bring it in correspondence with the area (g) of the hose (7).

Tighten the clip (7).

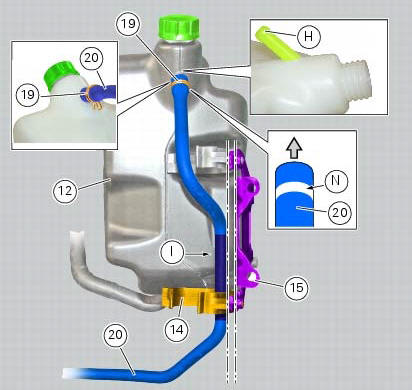

Fit the clip (19) on the hose (20).

Insert completely the hose (20) on the upper fitting (h) of the expansion reservoir (5), so that the straight part (l) of the hose is parallel to the bracket (2) as highlighted by the axes (l) and (m).

Note

The hose (20) side to be inserted in the fitting (h) features the white padprinting (n).

Important

Once the assembly is completed, the hose (20) must be in contact with the internal surface of the hose clamp (1) as indicated.

Note

In case of difficulties during insertion of the hose (20) into the fitting (h) it is recommended to apply lubricant suitable for rubber to the fitting.

Block the hose (20) by means of the clip (19), by orienting it as shown.

Insert

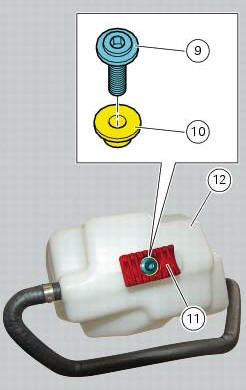

Insert the spacer with the collar (10) into the hole of the rubber mounting (11).

Fit the rubber mounting (11) as shown, by starting the screw (9).

Tighten the screw (9) to a torque of 8 nm +/- 10% (sect. 3 - 3, Frame torque settings).

Position the tank (12) with its hoses (7) and (20) and the support (15).

Position the pipes inside the clamps (14) and close them.

Tighten the screws (16) to the torque of 8 nm +/- 10% (sect. 3 - 3, Frame torque settings).

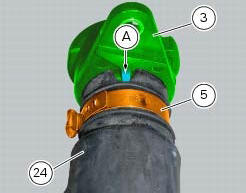

If hose (24) had been removed, insert the clip (5) on the hose (24) at the position shown.

Fit the union (3) on the hose (24) and secure it using the clamp (5).

Note

If hose (24) had been removed, insert the clip (5) on the hose (24) at the position shown.

Fit the union (3) on the hose (24) and secure it using the clamp (5).

Note

The union (3) must be oriented so that the groove on hose (24) matches the tab (a) on the hose. Orient the clamp (5) as indicated.

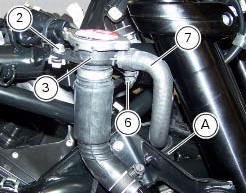

Refit the coolant circuit remote filler (4).

Position the union (3) on the frame by tightening the screw (2) to a torque of 5 nm +/- 10% (sect. 3 - 3, Frame torque settings).

Place hose (7) on the union (3) with clip (6) and tighten the latter to a torque of 1 nm +/- 10% (sect. 3 - 3, Frame torque settings).

Insert the hose (7) inside the hose guide (a).

Removal of the expansion tank

Removal of the expansion tank

Loosen the clamp (6), open the hose guide (a) and slide the hose (7) out of

the radiator.

Open clamps (14) and release the hoses that pass through them.

Loosen the screws (16).

Remove ...

Removal of the cooling system hoses and unions

Removal of the cooling system hoses and unions

Loosen the clips (21) that secure the radiator/thermostat sleeve (40) and the

radiator/plug sleeve (24) to the water

radiators.

Loosen clips (25) and (43) that secure the breather pipe ...

Other materials:

Units of measurement modification function

This function allows you to change the units of measurement

of the displayed values.

To access the function it is necessary to view the "setting" menu page 48, using

button (1, fig. 14) ?"" or (2, fig.

14) ?" " select the "set units" function

and pre ...

Refitting the hands free

Reassembly is a reversal of the removal procedure: in particular apply

prescribed threadlocker to screws (2) and tighten

them to a torque of 20 nm +/- 10% (sect. 3 - 3, Frame torque settings).

If the hands free button has been previously removed, when refitting it insert

the spring (6) on pi ...

Changing and cleaning the air filters

The air filter must be replaced at the intervals described in the "scheduled

maintenance chart" (sect. 4 - 2).

Work on the vehicle right side, loosen screws (1) that secure the intake duct

(2) to the filter box, and the radiator

retaining screw (3); recover the washer (4).

Remove the in ...