Ducati Diavel Service Manual: Refitting the external components

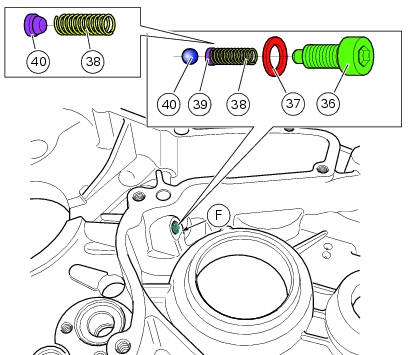

Fit the cap (39) on spring (38) until it engages.

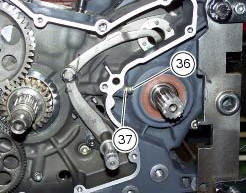

Mount ball (40), spring (38) with cap (39), washer (37) and screw (36) on the chain side half-casing by starting the screw into hole (f).

Note

The spring (38), with cap (39), must be oriented as shown.

Tighten the screw fully home to a torque of 10 nm (min. 9 Nm - max. 11 Nm).

Make sure that the o-rings (22) are fitted on the crankcase.

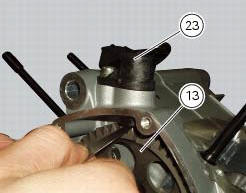

Fit the engine pickup (23) in its seat in the crankcase half.

Start the screw (25) with washer (26), and tighten it to a torque of 10 nm (min. 9 Nm - max. 11 Nm) (sect. 3 - 3, Engine torque settings).

Use a feeler gauge to check the clearance between the engine sensor (23) and the timing gear (13). The value must be Between 0.6 And 0.8 Mm.

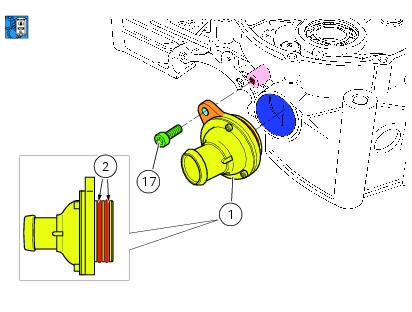

Check the condition of o-rings (2) and renew if necessary.

Install the oil vapour breather valve (1) in the crankcase along with o-rings (2), previously lubricated.

Tighten the screw (17) to a torque of 10 nm (min. 9 Nm - max. 11 Nm) (sect. 3 - 3, Engine torque settings).

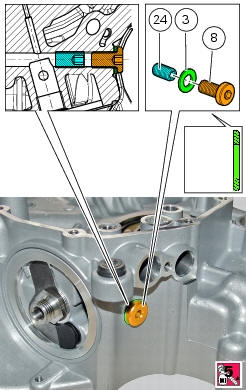

Position the by-pass spring (7) on the nipple (6) and apply the recommended threadlocker to the end of the nipple to be screwed in the crankcase half. Screw oil filter cartridge fitting (6) fully into the crankcase half, positioning the spring in the seat between the two notches (a). Tighten the nipple to a torque of 42 nm (min. 38 Nm - max. 46 Nm) (sect. 3 - 3, Engine torque settings).

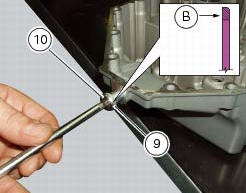

Fit the seal (9) on the oil drain plug (10). Position the seal that the side with the square edge (b) is facing the chain side crankcase half.

Clean the plug thread, apply a string of three bond tb1215 along the plug thread spreading it by the entire circumference (360).

Screw the exhaust plug (10) with relevant washer (9), and tighten it to a torque of 20 nm (min. 18 Nm - max. 22 Nm) (sect. 3 - 3, Engine torque settings).

Note

After tightening, remove any excess sealant.

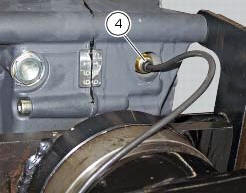

Refit idle gear position sensor (4) by means of the tool number 88713.3407.

Refit the mesh filter (a) (sec. 4 - 3, Changing the engine oil and filter cartridge).

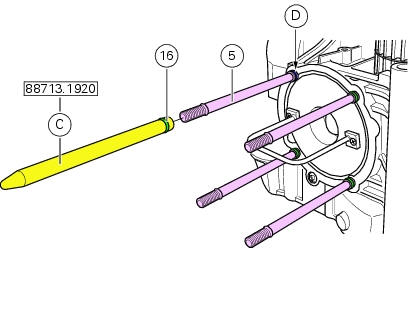

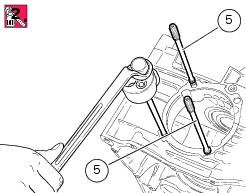

Check the condition of o-rings (16) of the stud bolts (5) and replace them if necessary.

Fit, using the tool (c), the o-rings (16) in the corresponding seats (d) of the stud bolts (5).

Fit the stud bolts (5) on crankcase half, by applying sealant on the thread and tightening them to a torque of 30 nm (min.

28 Nm - max. 32 Nm) (sect. 3 - 3, Engine torque settings). Use the appropriate commercial tool for this operation.

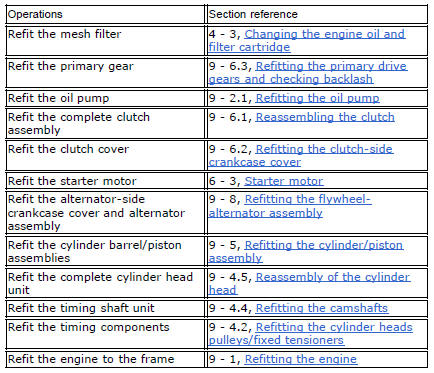

If removed, apply prescribed threadlocker on the dowel (24), tighten the latter to the torque of 15 nm (min.13.5 - Max.16.5) (Sect.3 - 3, Engine torque settings), insert the seal (3) on the service plug (8): the seal must be oriented so that the square edge faces the clutch-side crankcase half. Apply prescribed threadlocker on the plug thread (8), start it in the crankcase half and tighten it to a torque of 15 nm (min. 13 Nm - max. 17 Nm) (sect. 3 - 3, Engine torque settings).

Removing outer components

Removing outer components

Note

The following removal operations are required in order to renew and/or

clean the crankcase halves. If the original

crankcase halves are to be reused, then the removal of these components ...

Removal of the timing gears

Removal of the timing gears

Slide out driving gear (a) of timing gear pair (13) and remove the woodruff

key (14).

Relieve the staking on the lock washer (12) of the nut (11).

Restrain the driven timing gear by ...

Other materials:

Front brake lever

Pull the lever (1, fig. 94) Towards the twistgrip to operate the

front brake. The system is hydraulically assisted and you only

need to pull the lever gently.

The control lever (1, fig. 94) Features a dial adjuster (2, fig. 94)

For lever distance from the twistgrip on handlebar

adjustment.

...

Tubeless tyres

Front tyre pressure:

2.50 Bar (rider only) - 2.6 Bar (with passenger and/or bags)

rear tyre pressure:

2.50 Bar (rider only) - 2.6 Bar (with passenger and/or bags)

as tyre pressures are affected by changes in temperature

and altitude; check and adjust them whenever you are riding

in areas where ...

Renewal of the headlight

Disconnect the headlight connectors (a) from the main wiring (refer to the

tables of paragraph "routing of wiring on

frame", sect. 6 - 1).

Loosen nuts (2) that fix the front optical unit to the bottom yoke, and

recover the washers (3).

Remove the complete front optical unit by sliding ...