Ducati Diavel Service Manual: Refitting the front brake system

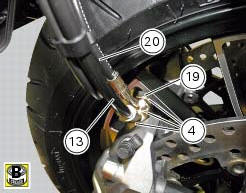

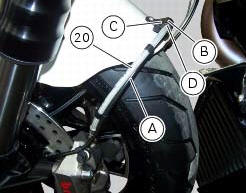

While refitting the system, pay special attention to the orientation of the pipe couplings (24) on the pump and the pipes (13) and (20) on the callipers (9) and (18).

Warning

If incorrectly positioned, the hose can affect brake operation and foul moving parts. Position the hose as shown in the figure.

When reconnecting the brake hose to the calliper or master cylinder, make sure to install the sealing washers (4) either side of the hose end fitting.

After having oriented the pipe fitting (24) tighten the screw (3) to a torque of 23 nm +/- 10% (sect. 3 - 3, Frame torque settings).

After having oriented the pipes (13) and (20) in the front brake callipers (18) and (9) tighten the special screws (19) and (25) to a torque of 23 nm +/- 10% (sect. 3 - 3, Frame torque settings).

Note

Make sure that internal pipe fitting (13) and the external pipe fitting (20) are installed in the left brake calliper (9).

Fit the left calliper (9) over the disk.

Apply the recommended grease to the screws (21).

Hand tighten the screws (21) to secure the callipers to the fork legs.

Operate the brake lever two or three times until the circuit is pressurised and force the pads against the brake disc.

Repeat the operation for the right brake calliper (18).

Hold the lever pulled towards the twistgrip and tighten the calliper screws (21) to the torque of 45 nm +/- 5% (sect. 3 - 3, Frame torque settings).

Insert brake rubber block (d) into grommet (b) and ensure it is centred.

Fold hose clip (b) and fasten it by starting the screw (c) in its thread.

Insert hose (13) in bracket (17) and tighten screw (16) to a torque of 8 nm +/- 10% (sect. 3 - 3, Frame torque settings).

For correct position of the ties fastening the abs sensor cable (a) to front brake lines (20), please refer to sect. 7 - 6, Flexible wiring/hoses positioning.

Refitting the brake disks

Refitting the brake disks

Before refitting the brake disc to the wheel, clean all contact surfaces

thoroughly and smear a medium strength

threadlocker on the threads of retaining screws (5).

Operating on the left side, f ...

Rear brake

Rear brake

Rear speed sensor (abs)

Screw

Washer

Spring

Brake switch (rear)

Brake lever (rear)

Rear pump - control unit pipe

Sealing washer

Pin

Bush

O-ring

Screw

screw

Rear brake ...

Other materials:

Refitting the gear interlock plunger and pawl assembly

On the special screw (3), fit the gear pawl lever (4), orienting it as shown

in the figure, the washer (2) with the square

edge side (d) facing the clutch-side crankcase half, and the spring (1),

positioning it so that the hook end (a) is facing

the gear pawl lever. Locate the hook end (a) of ...

Removal of the clutch

Note

For clarity, the figures show the engine removed from the frame.

Undo the fixing screws (1) and remove the ring (2) and the springs (3) from

the pressure plate (4).

Slide the pressure plate (4) paying attention to the circlips (6).

Remove the clutch control pin (14) and the ...

Checking the engine timing

Set the engine to the configuration described for the "checking and adjusting

the valve clearances", previously indicated.

Install tool 88765.1188 (G) in the spark plug bore to determine the piston tdc,

the gauges (h) on the tool 88765.1518

And the timing check tool (degree wheel (l) 887 ...