Ducati Diavel Service Manual: Refitting the front sprocket

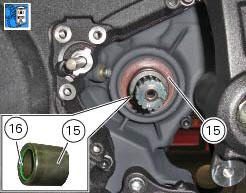

Grease the o-ring (16) and install it on the front sprocket spacer (15).

Fit the spacer, from the o-ring side, on the secondary shaft and drive it fully home against the inner ring of the bearing.

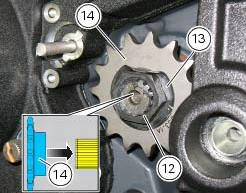

Check that the splines of the gearbox secondary shaft and the sprocket are in perfect condition.

Fit the engine pinion (14) on the gearbox secondary shaft by orienting it as indicated. Install the safety washer (13).

Tighten the nut (12) to the torque of 186 nm +/- 5% (sect. 3 - 3, Frame torque settings).

Bend the washer (13).

Fit the chain and close it using the tool with code 88713.1344 That was used to open the chain.

The tool is composed of a holder (a), punch (b), body (c) and two wrenches (d) and (e) and link plate holder (f).

Connect the two halves of the chain with the external link and manually fit the plate onto the pins.

Warning

Lubricate the pins abundantly; try to avoid touching them with your hands.

Fit the holder (a) onto the external link.

Fit the punch (b) into the body (c) and the plate holder (f).

Fit the body (c) onto the holder (a) which holds the chain in position.

Manually turn the bolt (g) until the plate holder (f) is seated against the plate itself.

Use wrenches (d) and (e) to turn the bolt (g) clockwise until the chain pin is in contact with the holder (f).

Remove the holder (a) from the tool.

Manually turn the bolt (g) until the punch (b) locates against the pin, taking care that they are aligned with each other.

Use wrenches (d) and (e) to turn the bolt clockwise until the punch (b) is seated against the chain plate.

To complete reassembly, repeat the entire procedure with the second pin.

Warning

Carefully check the two pins: the figure shows the correct result of the procedure.

Adjust the chain tension (sect. 4 - 3, Adjusting the chain tension).

Apply the recommended threadlocker to the screws (11).

Fit the sprocket cover (10) tightening the screws (11) to the torque of 6 nm+/- 10% (sect. 3 - 3, Frame torque settings).

Removing of the front sprocket

Removing of the front sprocket

Undo the screws (11) and remove the chain cover (10).

Loosen the chain (sect. 4 - 3, Adjusting the chain tension).

Remove the chain with the tool code 88713.1344.

The tool is composed of a ...

Replacing of the rear sprocket

Replacing of the rear sprocket

Lock the wheel axle rotation.

Remove the clip (1).

Loosen the locking nut (2) with a socket wrench.

Fully unscrew the nut (2) and remove the washer (3) and the flange (5) with the

sproc ...

Other materials:

Refitting the fuel tank

If the fuel tank has been disassembled into its component parts, reposition

all the parts as shown in the exploded view.

In particular:

tighten the screws (13) to a torque of 5 nm +/-10% (sect. 3 - 3, Frame torque

settings).

Refit the tank by inserting its rear side into the pin on the ...

Operating principle of dtc

The bbs receives the front and rear speed information from the abs over the

can. Then, the bbs sends the vehicle speed

information to be displayed on the dashboard over the can.

If the tangential speed of the rear wheel exceeds the tangential speed of the

front wheel by a given percentage, t ...

Trip 1 meter

This function shows the distance travelled since the trip

meter was last reset (in km or miles depending on the

specific application).

Holding the button (1, fig. 14)

pressed for 3 seconds

when this function is displayed resets the trip meter.

When the reading exceeds 9999.9, Distance tr ...