Ducati Diavel Service Manual: Refitting the gear interlock plunger and pawl assembly

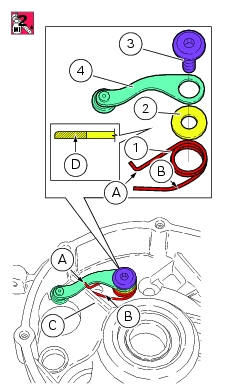

On the special screw (3), fit the gear pawl lever (4), orienting it as shown in the figure, the washer (2) with the square edge side (d) facing the clutch-side crankcase half, and the spring (1), positioning it so that the hook end (a) is facing the gear pawl lever. Locate the hook end (a) of the spring on the gear pawl lever as shown in the figure.

Apply threadlocker to the screw thread. Start the screw in the crankcase half. Position end (b) of the spring so that it rests against rib (c) of the crankcase half, as shown in the figure. Tighten the screw (3) to a torque of 18 nm (min. 16 Nm - max. 20 Nm) (sect. 3 - 3, Engine torque settings). Manually move the gear stopper to check for proper spring operation.

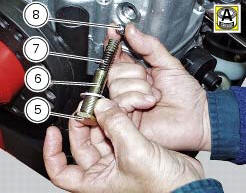

Grease and then fit the ball (8), spring (7), and seal (6) to the gear interlock plunger (5).

Lock the plunger (5) to a torque of 30 nm (min. 27 Nm - max. 33 Nm) (sect. 3 - 3, Engine torque settings).

Disassembly of gear interlock plunger and pawl assembly

Disassembly of gear interlock plunger and pawl assembly

Unscrew the interlock plunger screw (5) and remove the seal (6), spring (7)

and the detent ball (8).

Unscrew the clutch-side crankcase half screw (3) and remove the pawl (4),

washer (2) a ...

Refitting the gear selector lever

Refitting the gear selector lever

Position the gearbox drum selector fork in the centre of the gear rollers.

Position the gear selector lever (21) together with control shaft, spring and

plate into the chain-side crankcase half.

...

Other materials:

Refitting the rear wheel

Lubricate the wheel shaft threaded end with prescribed grease.

Insert the wheel shaft by matching (a) with pins (b).

Install spacer (3) with the conical surface faced to the wheel conical

surface, washer (2), apply prescribed grease to nut

(1) and insert it by hand (1).

Tighten the ...

Checking valve clearances

To check the valves clearance, it is necessary to have access to the cylinder

head covers and then remove the

components listed below.

Unscrew the two fixing screws (1) of the cover (2) according to the

crankshaft.

Fit the tool handgrip 88713.0123 In the holes of the generator cover t ...

Removal of the timing belt covers

Loosen the screws (4) securing the central external cover (1) and remove it

from the central side.

Undo the fixing screws (4) of the external cover (25) and remove it from the

vertical thermal unit.

Undo the fixing screws (4) of the external cover (3) and remove it from the

horizonta ...