Ducati Diavel Service Manual: Refitting the gear selector lever

Position the gearbox drum selector fork in the centre of the gear rollers.

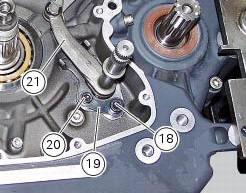

Position the gear selector lever (21) together with control shaft, spring and plate into the chain-side crankcase half.

Insert the screws (18) and (20) with the spacer (19).

Temporarily fit gear change lever (or a service lever) and engine pinion and shift to neutral gear.

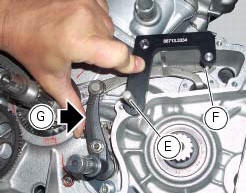

Place the tool 88713.3334 On the gear claw.

Place the tool 88713.3334 Inserting the clutch rod (e) into the tool hole, block the pin (f) of the tool in the gear claw pressing with the hand in the point (g) (claw stroke lock plate) towards the right, as shown in photo.

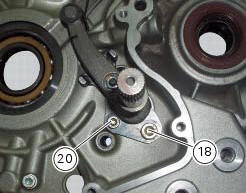

Tighten the screw (18) in this position to a torque of 36 nm (min. 34 Nm - max. 38 Nm) and screw (20) to a torque of 16 nm (min. 15 Nm - max. 17 Nm) (sect. 3 - 3, Engine torque settings).

Warning

Make sure that the gear selector lever fixing screws (18) and (20) are those indicated in our spare parts catalogue. They Must be screws of class 12.9 In order to respect the tightening torque indicated above (sect. 3 - 3, Engine torque settings).

Start tightening the first screw (18), and continue with screw (20).

Remove service tool no.

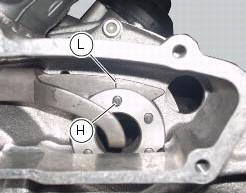

Check that the pin (h) placed on the gear drum is axially to the notch (l) on the gear claw (with gear in neutral).

With the gearbox in neutral, check that the lever travel is the same when shifting up and down. The same should apply when a gear is engaged.

Operate the gearchange lever and turn the front sprocket at the same time to check that all the gears engage when shifting up and down.

Remove the previously installed lever and sprocket.

Refitting the gear interlock plunger and pawl assembly

Refitting the gear interlock plunger and pawl assembly

On the special screw (3), fit the gear pawl lever (4), orienting it as shown

in the figure, the washer (2) with the square

edge side (d) facing the clutch-side crankcase half, and the spring (1),

...

Gearbox shafts

Gearbox shafts

Shim, thickness 1

Gearbox primary shaft

Shim, thickness 0.5

Needle roller bearing

5Th speed driving gear

Splined washer, thickness 0.5

Circlip

3Rd- 4th speed driving gear

6Th sp ...

Other materials:

Electrical power for lighting and signalling devices

The front and rear running lights consist of led units with light conduits.

As a result, the light source is not visible as the

light is diffused through the surface of the light conduit.

These two images illustrate the front and rear running lights with light

conduits.

The figure ...

Stored lap erase function

This function erases the stored laps.

To access the function it is necessary to view the "setting" menu page 48, using

button (1, fig. 14) ?"" or (2, fig.

14) ?"" select the "lap" function and

press the reset button

(12, fig. 12) To go to next page.

...

Removal of the front forks

Before removing the front forks, it is first necessary to remove the

following parts:

Loosen the clamp screws (1) holding the fork legs to the steering head (3).

Loosen the clamp screws (2) and (26) securing the fork legs to the bottom yoke

(4).

Withdraw the fork legs (5) and (6) downwar ...