Ducati Diavel Service Manual: Refitting the hands free

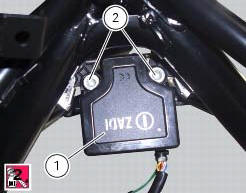

Reassembly is a reversal of the removal procedure: in particular apply prescribed threadlocker to screws (2) and tighten them to a torque of 20 nm +/- 10% (sect. 3 - 3, Frame torque settings).

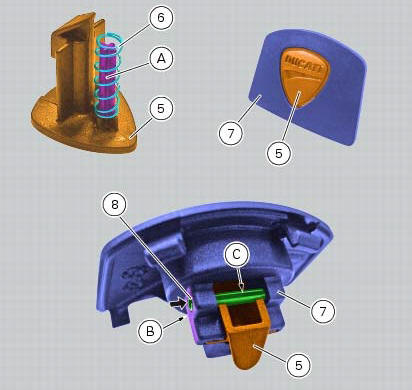

If the hands free button has been previously removed, when refitting it insert the spring (6) on pin (a) of button (5).

Introduce button (5) with spring (6) into the opening on the frame (7).

Lock the button (5) by means of a pin (8), by inserting it until reaching the surface (b) of the frame (7).

Note

Upon insertion of the pin (8), keep button (5) pressed in the direction indicated by the yellow arrow.

Warning

The opening (c) of the pin (8) must be on the opposite side of the of the surface touched by the button (5) when sliding (as shown in the figure).

To reposition the wiring refer to sect. 6 - 1, Routing of wiring on frame.

Removing the hands free

Removing the hands free

Loosen the screws (2) and remove the hands free system (1) from the frame.

...

Gearchange mechanism

Gearchange mechanism

Gearchange pedal

Bush

Rubber pad

Pin

O-ring

Gearchange lever tie-rod

Screw

Gearchange lever

Washer

Screw

Ball joint

Nut

Nut

Nut with left-hand thread

Lh ball joint

...

Other materials:

Maintenance indicator

This function indicates that the vehicle is about to or has

travelled a distance for which an authorised ducati service

centre should be contacted to have the general maintenance

or oil change performed.

Maintenance table

First warning - oil service 1000 km

The first warning is activated a ...

Refitting the tail light

Fit the spacers with collar (3) into the rear vibration dampers (2) located

on the gloves compartment (23).

Note

Two spacers (3) must be inserted inside and outside on the right side and

two spacers (3) must be inserted inside and

outside on the left side.

Insert the split vibration damp ...

Removal of the handlebar

Unscrew and remove the screws (3) securing the upper clamp (1).

Remove the upper clamp (1).

Remove the handlebar (4) from its seat on the steering head.

To remove the grips (5), refer to the exploded view at the beginning of this

chapter.

...