Ducati Diavel Service Manual: Refitting the intake manifold and coolant union

Apply prescribed threadlocker to the fitting (12), start it with seal (24) and tighten it to a torque of 2.5 Nm (min. 2 Nm - max. 3 Nm) (sect. 3 - 3, Frame torque settings).

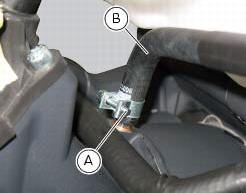

Install the pipe (b) and tighten the clamp (a) to the torque of 1 nm +/- 10% (sect. 3 - 3, Engine torque settings).

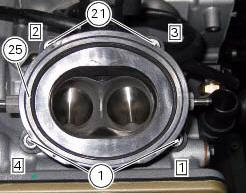

Check that the mating surfaces of the cylinder head and manifold are perfectly flat and clean and install the intake manifold (25) on the cylinder head.

Lock the fixing screws (21) to the torque of 10 nm (min. 9 Nm - max. 11 Nm) (sect. 3 - 3, Engine torque settings) in a cross-pattern sequence (1-2-3-4).

Removal of the intake manifold and coolant union

Removal of the intake manifold and coolant union

Loosen the clips (f) and remove the hoses (t).

Remove the manifolds (25) undoing the screws (21).

Loosen the clamp (a) and remove the hose (b). Remove the union (12) and

recove ...

Valves - rocker arms

Valves - rocker arms

Closing rocker arm shaft

Opening rocker arm shaft

Opening rocker arm

Closing rocker arm (left)

Valve opening shim

Half rings

Valve closing shim

Sealing ring

Valve guide

Exhaus ...

Other materials:

Removal of the crankshaft/connecting rods assembly

After separating the crankcase halves, withdraw the crankshaft (6) complete

with connecting rods (2).

...

Belly fairing

Rh belly fairing

Lh belly fairing

Special screw

Nylon washer

Screw

Central belly fairing

Oil cooler shield

Special screw

Clip

Washer

Clip

Screw

Bracket

Screw

Spare parts catalogue

Diavel abs belly fairing

Diavel carbon

abs

belly fairing

Important

Bold refere ...

Changing bulbs

Changing the headlight bulbs

Before replacing a burnt out light bulb, ensure that the replacement bulb has

the same voltage and power rating as

specified for the lighting device in question (sect. 3 - 1.1, Lights/instrument

panel).

Warning

The halogen light bulbs in the headlight become hot ...