Ducati Diavel Service Manual: Refitting the lubrication system

Note

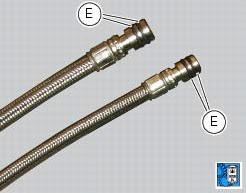

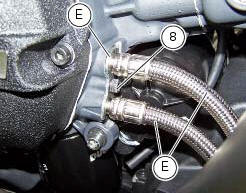

Before fitting the pipes (7), it is recommended to check the presence of the o-rings (e). Lubricate them by using engine oil.

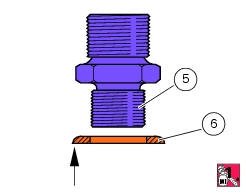

If the nipples (5) have been removed from the radiator insert a washer (6) on each nipple (5) and apply specific threadlocker on threads on the radiator side.

note

The washers (6) must be inserted on the side of the nipples (5) which represent the thread with the smaller diameter, and must be oriented with the cutting edge to the radiator.

Start the nipples (5) on the oil cooler (1) and tighten them to a torque of 23 nm +/- 10% (sect. 3 - 3, Frame torque settings).

Lubricate the nipples threads (5) with engine oil.

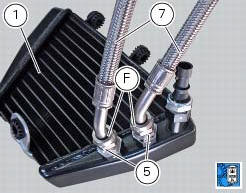

Attach the hoses to the nipples (5), finger-tightening the ring nuts (f) of the hoses on the nipples.

Tighten the ring nuts (f) to a torque of 18 nm +/- 5% (sect. 3 - 3, Frame torque settings).

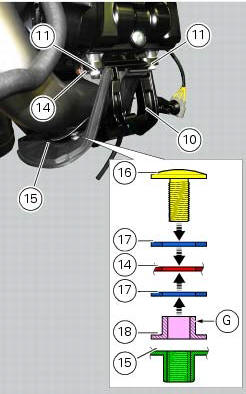

If the horizontal exhaust heat guard assembly was removed, on refitting insert the screw (16) with a washer (17) in heat guard (14) to join it to the exhaust protection (15), and then fit the other washer (17) with spacer (18) on the protruding end of the screw.

Note

The spacer (18) must be oriented with the collar (g) facing the heat guard (14).

Fit the heat guard (14) on the exhaust protection (15) by tightening the screw (16) to a torque of 3 nm +/- 10% (sect. 3 - 3, Frame torque settings).

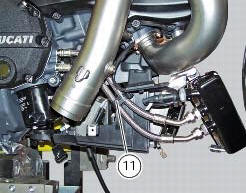

Fit the heat guard (14) and heat protection (15) assembly on the horizontal cylinder head with support (10) by tightening the screw (11) to a torque of 10 nm +/- 10% (sect. 3 - 3, Frame torque settings).

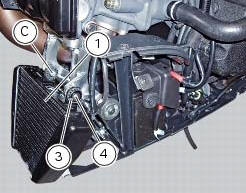

Check that the vibration damper mounts are present on the oil cooler (2).

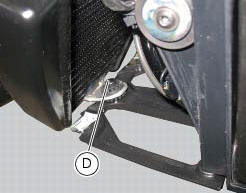

Fit the oil cooler (1) by inserting it first into pins (c) and (d) of the supporting bracket.

If you encounter any difficulties, apply lubricant for rubber to the pin (d).

Insert the spacer (3), the screw (4) and start the screw (4).

Position the pipes (7) in the crankcase half. Position the plate (9).

Tighten the screw (8) to the torque of 10 nm +/- 10% (sect. 3 - 3, Frame torque settings).

Tighten the screw (4) to the torque of 6 nm +/- 10% (sect. 3 - 3, Frame torque settings).

Close the pipe grommet (11).

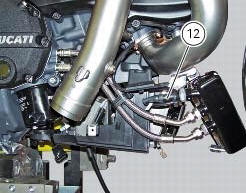

If previously removed, place the sensor (12) with washer (13) on cooler and tighten it to a torque of 19 nm +/- 10% (sect. 3 - 3, Frame torque settings).

Connect the sensor (12) to the main wiring.

Removal of the lubrication system

Removal of the lubrication system

Disconnect the sensor (12) of the main wiring.

Open the pipe grommet (11).

Undo the screw (8) and slide out the plate (9).

Slide the tubes (7) out of the half-casing having care not to ...

Cooling system

Cooling system

...

Other materials:

Air temperature sensor

Introduction

The engine control system on the diavel uses a sensor that measures air

temperature. This sensor has a resistance of

ntc type (negative temperature coefficient), that reduces its own value when the

temperature increases. The air

temperature sensor allows the engine control unit t ...

Removal of the movable tensioner/timing belt

Loosen the nut (8) and remove the washer (7) and the tensioner pulley (9)

from the pin (12) on the cylinder head.

Remove the timing belt (14) from the horizontal cylinder assembly.

Important

If the belts are to be re-used, mark the direction of rotation with an

arrow and also mark the cylin ...

Tips for use on the track

We recommend level 8 be used for a couple of full laps (to

allow the tyres to warm up) in order to get used to the

system. Then try levels 7, 6, etc., In succession until you

identify the dtc intervention level that suits you best (always

try each level for at least two laps to allow the tyres t ...