Ducati Diavel Service Manual: Refitting the number plate holder

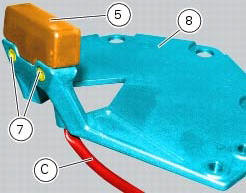

Place the number plate light (5), as indicated, on the number plate holder plate (8) and tighten the screws (7) to a torque of 2 nm +/- 10% (sect. 3 - 3, Frame torque settings).

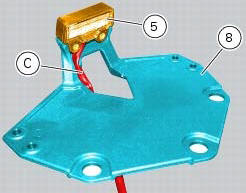

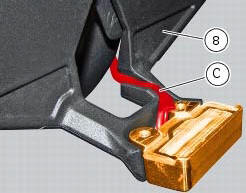

Thread the number plate light wiring (c) into the opening in the number plate holder plate as shown.

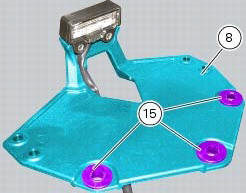

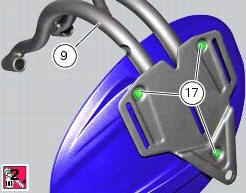

Fit the vibration dampers (15) in the corresponding holes of the number plate holder plate (8). Position the splashguard (16) on the number plate support subframe (9).

Apply prescribed threadlocker on the screw threads (17).

Fix the splashguard (16) by tightening the screws (17) to a torque of 5 nm +/- 10% (sect. 3 - 3, Frame torque settings).

Position the number plate light wiring (c) into the seat in the number plate holder plate (8) as shown.

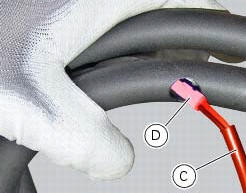

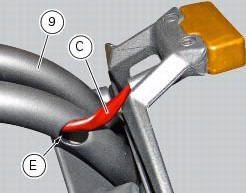

Insert the connector (d) of the number plate light wiring (c) into the hole (e) in the number plate support subframe (9), threading it out of the hole on the opposite side.

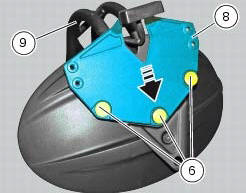

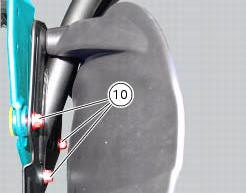

Fit the number plate holder plate (8) to the number plate support subframe (9), fitting the special screws (6) into the vibration dampers and starting the nuts (10) on the opposite side.

Note

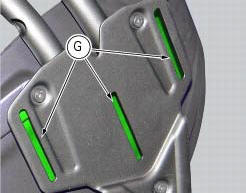

Slide the plate (8) along the slots (g) in the subframe (9) until bringing it all the way towards the bottom side.

Tighten the special screws (6) to a torque of 5 nm +/- 10% (sect. 3 - 3, Frame torque settings), by holding the nuts (10) on the opposite side.

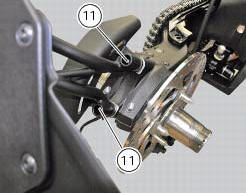

Reposition the assembly on the swingarm and tighten the screws (11) to a torque of 25 nm +/- 10% (sect. 3 - 3, Frame torque settings).

Removal of the licence plate holder

Removal of the licence plate holder

Disconnect connector (5) of the number plate holder wiring from the main one.

Release the number plate holder light cable from the ties and the cable grommets

as indicated in sect- 7 - 6, fle ...

Removal of the tail light

Removal of the tail light

Disconnect the connectors (a) and (b) of the tail lights (1) and (13).

Loosen the screws (4) and slide the tail lights (1) and (13) to the rear side;

recover the four spacers (3) and the wash ...

Other materials:

Seat

Seat

Seat cover

Rubber mounting

Special screw

Plate

Latch

Spare parts catalogue

Diavel abs seat

Diavel carbon

abs

seat

Important

Bold reference numbers in this section identify parts not shown in the

figures alongside the text, but which can be found in

the exploded view ...

Indicator trip time - trip time

This function shows the vehicle trip time.

The calculation is made considering the time travelled since the last trip 1

reset. When trip 1 is reset, the value is set to

zero.

The active phase calculation occurs when the engine is running and the vehicle

is stopped (when the vehicle is not ...

Removal of the tail light

Disconnect the connectors (a) and (b) of the tail lights (1) and (13).

Loosen the screws (4) and slide the tail lights (1) and (13) to the rear side;

recover the four spacers (3) and the washers

(14).

...