Ducati Diavel Service Manual: Refitting the oil pump

If removed, apply specific threadlocker on the bushing (7) outer thread, and screw it in the crankcase half, observing the height.

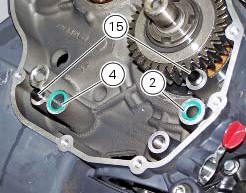

Position the reference bushings (15) and the oil sealing o-rings (2) and (4) according to the crankcase lubrication channels.

Position the oil pump on the crankcase and tighten screws (9) to a torque of 26 nm (min. 23 Nm - max. 29 Nm) and the screw (10) to a torque of 10 nm (min. 9 Nm - max. 11 Nm) (sect. 3 - 3, Engine torque settings).

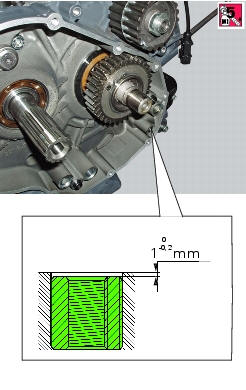

Check the gear clearance with the driving pinion by fixing a dial gauge (a), equipped with the appropriate traces, to the crankcase half.

Position the dial gauge stylus on one tooth of oil pump gear and set the gauge to zero in this position.

Move the gear slightly to measure the backlash; take four readings in diametrically opposed positions of the gear.

The clearance should be 0.10 Mm.

Reassembly of the oil pump

Reassembly of the oil pump

Check that the circlip (3) and tongue (13) are present on the pump.

Fit the pump drive gear (12) on to the oil pump and secure it by installing the

circlip (6) in its groove.

Insert the by-p ...

Oil cooler

Oil cooler

Oil cooler

Vibration damper mount

Spacer

Screw

Nipple

Aluminium gasket

Oil delivery hose

Screw

Plate

Bracket

Screw

Engine oil pressure sensor

Sealing washer

Heat guard ...

Other materials:

Timing system

Central external cover

Air filter

Horizontal cylinder timing belt cover

Screw

Filter support

Screw

Washer

Nut

Tensioner pulley assembly

Circlip

Camshaft pulley

Tensioner pin

Idler pulley assembly

Timing belt

Nut

Key

Spacer

Camshaft pulley

Driveshaft pulley ...

Refitting the cylinder/piston assembly

If new units are used, it is necessary to couple the cylinders and pistons of

the same selection (see paragraph "overhaul Of the cylinder

barrel/piston components" of this section).

If the pistons have been separated from their cylinders, before reassembling

these components, position the p ...

Overhauling the front forks

Note

It is advisable to loosen the top cap (14) when the fork is still fitted

to the motorcycle.

Note

The specific tools for the revision of the fork, are described in sect. 3

- 4, Specific tools for the frame.

Loosen the spring preload adjuster before unscrewing the plug (14).

Unscrew th ...