Ducati Diavel Service Manual: Refitting the primary drive gears and checking backlash

Fully degrease the crankshaft splined end and the corresponding spline on the primary drive gear.

Position the spacer (c) onto the crankshaft.

Fit the driving gear (b) onto the crankshaft with the oil pump drive sprocket facing the crankcase.

Temporarily secure the gear with the washer (4) and nut (3).

Important

If fitting a new primary driving gear (b), check the backlash.

To check the clearance, temporarily fit the clutch bell (1) complete with the primary driven gear (a) on the gearbox primary shaft. Fix a dial gauge to the engine crankcase, positioning the stylus against a gear tooth.

Turn the driven gear (a) to mesh the teeth and check that clearance ranges between 0.05 And 0.07 Mm.

Repeat the check at 16 different points of the driven gear.

If the measured values are outside the permissible tolerance limits, try changing the position of driven gear (a) on the primary shaft, leaving the driving gear (b) on the crankshaft. If still outside tolerance values, renew the whole primary drive gear pair.

After checking backlash, fit the bush 88713.3406 On a torque wrench, lock the pinion (b) with the holding tool 88713.3417.

Position the washer (4) and the ring nut (3). Use the special tool 88713.3406 To tighten the ring nut (3) to a torque of 190 nm (min. 171 Nm - max. 209 Nm) (sect. 3 - 3, Engine torque settings).

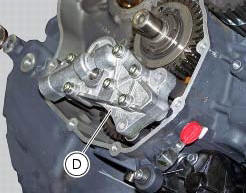

Refit the oil pump (d) and check the clearance between the oil pump gear and primary drive gear on the crankshaft (sect. 9 - 2.1, Refitting the oil pump).

Thoroughly degrease the mating surfaces of the clutch bell (1).

Fit the spacer (2) onto the primary shaft. Fit the clutch housing (1) along with the driven gear (a).

Removal of the primary drive gear

Removal of the primary drive gear

Withdraw the clutch housing (1) complete with driven gear of the primary pair

(a).

Remove the inner spacer (2).

Remove the oil pump (d) (sect. 9 - 2.1, Removal of the oil pump).

L ...

Gearbox assembly

Gearbox assembly

...

Other materials:

Refitting the rear wheel

Lubricate the wheel shaft threaded end with prescribed grease.

Insert the wheel shaft by matching (a) with pins (b).

Install spacer (3) with the conical surface faced to the wheel conical

surface, washer (2), apply prescribed grease to nut

(1) and insert it by hand (1).

Tighten the ...

Dashboard

Note

The dashboard is supplied as a single component; its internal components

cannot be renewed separately.

Important

Whenever the dashboard is renewed, the ignition key programming procedure

must be repeated.

Loosen the nuts (2) to remove the master dashboard (1) from its seat and

disconn ...

Refitting the front brake system

While refitting the system, pay special attention to the orientation of the

pipe couplings (24) on the pump and the pipes

(13) and (20) on the callipers (9) and (18).

Warning

If incorrectly positioned, the hose can affect brake operation and

foul moving parts. Position the hose as shown in th ...