Ducati Diavel Service Manual: Refitting the rear brake calliper

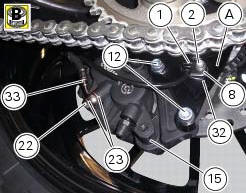

When replacing the brake pipes (33) or removing one of the rear braking system components, pay special attention to the position of the couplings on the pump and the calliper.

Warning

If incorrectly positioned, the hose can affect brake operation and foul moving parts. Position the hose as shown in the figure.

Remember to fit the copper faced sealing washers (23) to the hose end fitting when reconnecting the brake pipe to the brake calliper (15).

After orientating the fitting, lock the special screw (22) to a torque of 23 nm +/- 10% (sect. 3 - 3, Frame torque settings).

If the speed sensor (1) was removed, fit it on the calliper holder bracket (a) with the spacer (8) and the washer (32) and tighten the screw (2) to a torque of 10 nm +/- 10% (sect. 3 - 3, Frame torque settings).

Note

The gap between the sensor (1) and the brake disc fixing screw must be within 0.6 To 2.2 Mm.

If it is necessary to remove the calliper holder bracket (a) in order to refit it, see sec. 7 - 13, Refitting the rear wheel eccentric hub and rear wheel shaft.

Insert the rear brake calliper (15) on the brake disk, aligning it with the holes of the calliper mounting bracket (a).

Grease the screws (12) and tighten to the torque of 25 nm +/- 5% (sect. 3 - 3, Frame torque settings).

In order to fit the pipe (33), the speed sensor (1) and the retaining clamps follow instructions in sect. 7-6, Flexible wiring/hoses positioning.

Removal of the rear brake disc

Removal of the rear brake disc

Remove the rear eccentric hub (sec. 7 - 13, Removal of the rear wheel

eccentric hub and rear wheel shaft).

Undo and remove the four fixing screws (13) of the brake disk to the wheel axle

and re ...

Other materials:

Background setting function for the instrument panel on tank - dashboard 1

This function allows setting the "background" of the

instrument panel on tank.

To access the function it is necessary to view the "setting" menu page 48, using

button (1, fig. 14) ?"

" or (2, fig. 14) ?" " select the "back light" function

a ...

Side stand button

Introduction

The side stand button is located on the side stand. Together with the signal

from the clutch button and the neutral signal

generated by the gear sensor (transmitted to the engine control unit over the

can line), the side stand position signal is

used to enable or disable engine s ...

Refitting the rear sprocket

Check the cush drive bushes (6) condition and, if necessary, replace them by

removing them from the flange.

Refitting is the reverse of removal.

Apply recommended grease on the rear sprocket flange (5) external diameter.

Place the rear sprocket flange (5) on sprocket (17) by inserting it ...