Ducati Diavel Service Manual: Refitting the rear footrests

Note

The refitting of the rear footrests is described for the right side but it is the same for both.

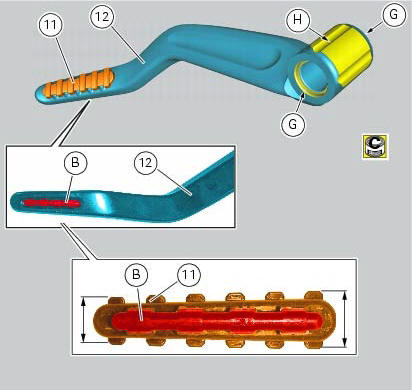

If previously removed, refit the rubber footrest (11) on the rear rh footrest (6), by pushing it until pad (b) engages in the other side.

Note

The rubber footrest (11) side featuring the least width must be faced to the outer side of the footrest (12).

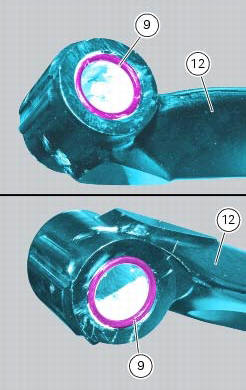

Apply recommended grease to the seats (g) of the o-rings and in area (h) on the rear rh footrest (12).

Place o-rings (9) in the relevant seats of the footrest (12).

Position footrest (12) as shown, on the rear subframe rh bracket; make sure that the previously fitted o-rings do not come out of the relevant seats on the footrest (12).

Fit washer (8) between footrest (12) and the rear subframe rh bracket.

Fix the footrest (12) by starting the pin (13) smeared with specified threadlocker.

Tighten the pin (13) to a torque of 30 nm +/- 10% (sect. 3 - 3, Frame torque settings).

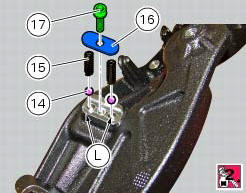

If previously removed, apply recommended grease into the holes (l) and insert balls (14) and springs (15) into the relevant holes of the rear subframe rh bracket.

Apply prescribed threadlocker on the screw thread (17).

Fit the cap (16) and tighten the screw (17) to a torque of 10 nm +/- 10% (sect. 3 - 3, Frame torque settings)

Removing of the rear footrests

Removing of the rear footrests

The removal of the rear footrests is described for the right side but it is

the same for both.

Undo the pin (13) and remove the rh rear footrest (12) from the frame.

Recover washer (8) and the ...

Stands

Stands

Side stand

Side stand switch

Screw

Plate

Screw

Inner spring

Outer spring

Nut

Rotation pivot

Screw

Screw

Screw

Nut

Clearance adjuster

Spare parts catalogue

Diavel a ...

Other materials:

Removal of the front forks

Before removing the front forks, it is first necessary to remove the

following parts:

Loosen the clamp screws (1) holding the fork legs to the steering head (3).

Loosen the clamp screws (2) and (26) securing the fork legs to the bottom yoke

(4).

Withdraw the fork legs (5) and (6) downwar ...

Resetting turn indicators not possible - accessing dashboard menu not

possible

Fault codes

Dds: no fault code displayed

Dashboard: no fault code displayed

Location of connections and components

Location of left hand handlebar switchgear set connection.

Pin numbering for wiring harness side dashboard connector.

Checks

Test turn indicator reset button function. Wh ...

Removing of the cylinder head pulley/fixed tensioner

Insert the tool code 88713.1806 In the pulleys to lock their rotation and use

the bush supplied to loosen the fixing nuts

(21) of the pulleys.

important

On reassembly, always use new nuts.

Remove the nuts (21) and the pulleys (11) from the camshafts.

Loosen the nut (8), and remove the was ...