Ducati Diavel Service Manual: Refitting the rear sprocket

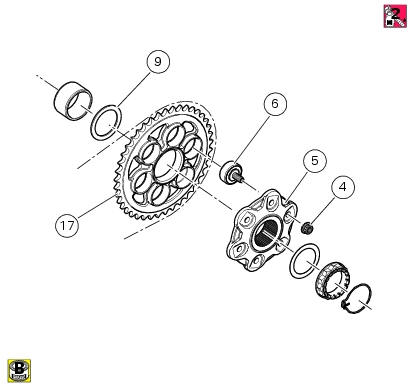

Check the cush drive bushes (6) condition and, if necessary, replace them by removing them from the flange.

Refitting is the reverse of removal.

Apply recommended grease on the rear sprocket flange (5) external diameter.

Place the rear sprocket flange (5) on sprocket (17) by inserting it on cush drive damper pins (6).

Apply prescribed threadlocker on the nut threads (4).

Start the nuts on the cush drive damper pins (6) threaded side.

Tighten the nuts (4) to a torque of 44 nm +/- 10% (sect. 3 - 3, Frame torque settings), following a cross-pattern sequence.

Check for wear following the instructions given at the beginning of this section.

To refit the nut (2) follow the specifications for the wheel fixing nut, in sect. 7 - 2, Refitting the rear wheel.

Position the clip (1) as shown.

Washing the chain

Chains with o-rings must be washed in oil, diesel fuel or paraffin (kerosene).

Do not use fuel, trichloroethylene or other solvents which will damage the rubber o-rings. For the same reason use only sprays specifically formulated for use with o-ring chains.

Replacing of the rear sprocket

Replacing of the rear sprocket

Lock the wheel axle rotation.

Remove the clip (1).

Loosen the locking nut (2) with a socket wrench.

Fully unscrew the nut (2) and remove the washer (3) and the flange (5) with the

sproc ...

Lubricating the chain

Lubricating the chain

O-ring chains have sealed, life-lubed link studs and bushes. However, these

chains need lubricating at regular intervals to

protect metal parts of the chain and the o-rings.

Lubrication also ser ...

Other materials:

On/off switch on handlebar

Introduction

The on/off switch on the handlebar is used to switch the dashboard on and

off, if a key has been detected, and start the

engine.

With the switch turned to "run off" (centre position), pushing downwards

switches the dashboard on or off (activating

the button inside the switch). ...

Removal of the generator cover

Note

This operation is described for an engine removed from the frame since all

reassembly procedures are easier with the

engine on the bench.

Disconnect the connector (a) from the generator cable.

Unscrew the two retaining screws (7) of the centre cap (6) over the end of

the cranksh ...

Pin code change function

This function changes your four number pin code.

To access the function it is necessary to view the "setting"menu, using buttons

(1) "s" or (2) "t" to select the "pin code"

function and press the reset button (3) to enter the following page.

Note

If "insert new pin code" and the dashes "- - ...