Ducati Diavel Service Manual: Refitting the rear suspension

Lubricate the thread and underside of the special screw (1).

Insert the lower side of the shock absorber into the swingarm and insert the screw (1).

Tighten the screw (1) to a torque of 45 nm +/- 5% (sect. 3 - 3, Frame torque settings).

Lubricate bushes (5) and (6) with recommended grease.

Position the upper part of the shock absorber assembly on the supporting plate and fit bush (6) on the lh side of the vehicle, and bush (5) on the right side.

Tighten the bush (5) to a torque of 45 nm +/- 10% (sect. 3- 3, Frame torque settings) while holding the bush (6).

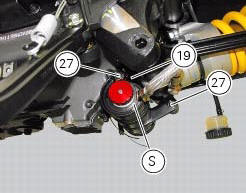

Refit the tank assembly (s) of the shock absorber on support (19) and tighten the screws (27) to a torque of 10 nm +/- 10% (sect. 3 - 3, Frame torque settings).

Reposition the assembly (34) on the frame and tighten the screws (22) to a torque of 10 nm +/- 10% (sect. 3 - 3, Frame torque settings).

Reassembly of rear shock absorber - rocker arm - linkage assembly

Reassembly of rear shock absorber - rocker arm - linkage assembly

Once the needle roller bearings (9) have been removed from the rocker arm

(18), upon reassembly fit a new needle roller

bearing (9) on drift part no. 88713.1071 And lubricate with recommended greas ...

Removal of the shock absorber support

Removal of the shock absorber support

Remove the rear brake master cylinder (sect. 7 - 4, Removing of the rear

brake control).

Remove the rear shock absorber (see removal of the rear shock absorber of this

section).

Loosen the s ...

Other materials:

Refitting the gear selector lever

Position the gearbox drum selector fork in the centre of the gear rollers.

Position the gear selector lever (21) together with control shaft, spring and

plate into the chain-side crankcase half.

Insert the screws (18) and (20) with the spacer (19).

Temporarily fit gear change lever (or a ...

Disassembly of the generator cover

Undo the three stator retaining screws (25) and the two retaining screws (9)

of the two cable grommet bracket (10) from

inside the generator cover.

Remove the stator (2) and the cable grommet bracket (10).

The generator-side crankcase cover is fitted with a bearing (27), held in

pla ...

Engine setting function (engine power control)

This function customises engine power and output.

To access the function it is necessary to view the ""setting" menu", using

buttons (1) "s" or (2) "t" select the "riding

mode" function and press the reset button (3) to enter the following page.

Use button (1) "s" or (2) "t" to select the r ...