Ducati Diavel Service Manual: Refitting the rear wheel

Lubricate the wheel shaft threaded end with prescribed grease.

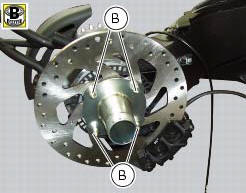

Insert the wheel shaft by matching (a) with pins (b).

Install spacer (3) with the conical surface faced to the wheel conical surface, washer (2), apply prescribed grease to nut (1) and insert it by hand (1).

Tighten the nut (1) to a torque of 230 nm +/- 10% (sect. 3 - 3, Frame torque settings) checking that the hole on the nut is aligned with those in the wheel axle.

Fit the clip (6), inserting the end of one of the holes in the axle, orienting it a shown.

Overhauling the rear wheel

Overhauling the rear wheel

Inspect the condition of the rear wheel.

As the wheel rim has no bearings, it should be supported using the service tool

code 88713.2951.

Note

This service tool can also be used to install the ...

Front brake control

Front brake control

Front brake master cylinder

Brake lever

Special screw

Sealing washer

Screw

Phonic wheel

Brake disc

Pin

Left brake calliper

Boot

Bleed valve

Spare stand

Control unit - fr ...

Other materials:

Reassembling the water radiator unit

The procedure is the same for both radiators.

Check the presence of clips (1) at the positions of the external coolant

radiator cover (23).

If removed, fit the front turn indicator (32) on the cover (23) and tighten the

screws (27) to 2 nm +/- 10% (sect. 3 - 3,

Frame torque settings).

No ...

Tool kit and accessories

The tool kit (2) is located under the seat (1) while the owner’s

manual is housed in the compartment under the seat.

The tool kit includes:

Fuse pliers;

Two helmet anti-theft cables;

Screwdriver;

Screwdriver handle;

14/16 Mm box wrench;

6 Mm rod;

3 Mm allen wrench;

4 Mm allen ...

Running lights not working

Fault codes

Dds: no fault code displayed.

Dashboard: no fault code displayed.

Location of connections and components

(A) low / high beam and parking light connections

rear running light and stop light connection.

Pin numbering of wiring harness side bbs unit connection.

Checks

The ...