Ducati Diavel Service Manual: Refitting the rear wheel eccentric hub and rear wheel shaft

Refitting is the reverse of removal, with attention to the following points.

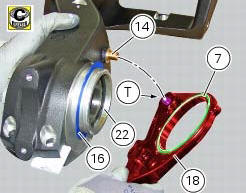

If the calliper bracket locating pin (14) was removed, apply the recommended threadlocker on reassembly.

Tighten the pin (14) to the torque of 33 nm +/- 5% (sect. 3 - 3, Frame torque settings).

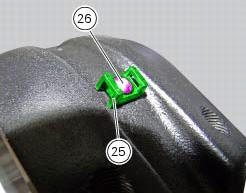

If previously removed, refit the cable grommet (25) as shown in the figure and tighten the screw (26) to a torque of 1 nm +/- 10% (sect. 3 - 3, Frame torque settings).

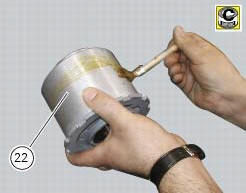

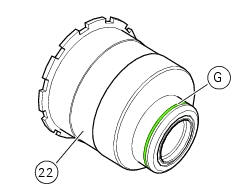

Before refitting apply some recommended grease to the eccentric hub (22) external surface.

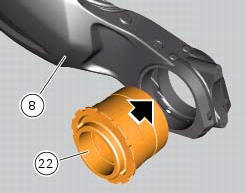

Insert the hub (22) fully home on the swingarm (8).

Note

During this operation force the hub seat open on the swingarm enough to fit the hub (22).

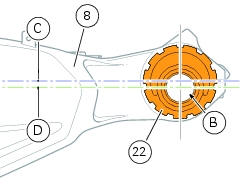

Check that the eccentric hub (22) with respect the swing arm (8) features the horizontal axis (d) of the hub bore (b) under the horizontal axis (c) of the hub seat.

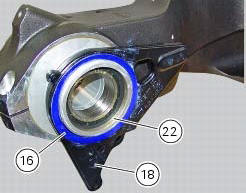

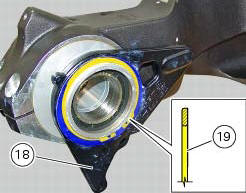

Apply grease on rings (17) and place them in their seat of the plate (18). Fit the washer (16) on the eccentric hub (22).

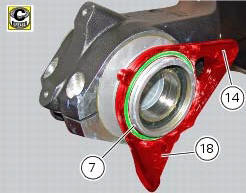

Place the plate (18) on the swingarm: the pin (14) must match with the blind slot (t) on the plate (18).

Refit the other washer (16) on the eccentric hub (22).

Block the plate (18) after installing circlip (19) in its groove (g) on hub (22), and setting it with its square edge outward.

Note

After this operation visually check that the circlip is perfectly inserted in the groove (g).

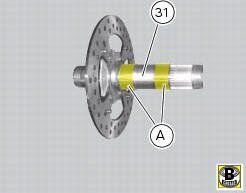

Apply an even coating of the recommended grease in the areas (a) of the axle (31).

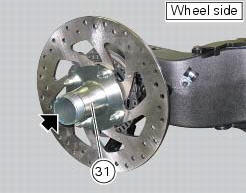

Insert the rear wheel shaft (31) in the hub (22).

Ensure the stub axle (31) is seated in the hub.

Fit the inner ring (21) on the wheel shaft (31).

Insert the inner ring (21) in the hub.

Apply the recommended grease to the screws (a) and tighten to the torque of 35 nm+/-5%(sect. 3 - 3, Frame torque settings) following the sequence 1-2-1.

Set the chain tension as described in sect. 4 - 3, "Adjusting the chain tension".

Removal of the rear wheel eccentric hub and rear wheel shaft

Removal of the rear wheel eccentric hub and rear wheel shaft

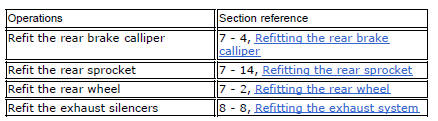

Before removing the eccentric hub, you must first remove the parts listed

below.

Slacken off the screws (34).

Remove the spacer (20) and the inner ring (21) on the chain side and remove the ...

Removal of the swingarm

Removal of the swingarm

Before removing the parts in question, you must first carry out the following

operations:

Remove the rear wheel eccentric hub as described in chapter "removal of the

rear wheel eccentric hub ...

Other materials:

Injectors

Introduction

The injectors used on the diavel are top feed units, meaning that fuel is fed

into the top of the injector itself. The

injectors contain a winding which raises a needle when electrically energised.

This opens the atomiser nozzle, through

which pressurised fuel is dispensed, gener ...

Refitting the fuel tank

If the fuel tank has been disassembled into its component parts, reposition

all the parts as shown in the exploded view.

In particular:

tighten the screws (13) to a torque of 5 nm +/-10% (sect. 3 - 3, Frame torque

settings).

Refit the tank by inserting its rear side into the pin on the ...

Removal of the exhaust system

Remove the silencer, as described in the paragraph "removing the silencer" of

this section.

Loosen the screws (28) and remove the exhaust by-pass valve cover (27).

Turn the exhaust valve pulley (a) to facilitate the throttle cable (25)

output.

Release the end fitting (b) of the cable ...