Ducati Diavel Service Manual: Refitting the side stand

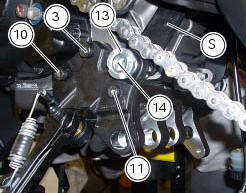

Place the stand plate on the rear shock absorber support; bring adjuster (14) in line with bracket (s) and start the screw (12) in the nut behind the bracket (s).

Insert the screws (11), (3) and (10) fully home in this order, but do not tighten.

Loosen the screw (12) with the relative nut, tighten the adjuster (14) to a torque of 0.6 Nm +/- 10% (sect. 3 - 3, Frame torque settings) and tighten the screw (12) to a torque of 2 nm +/- 10% (sect. 3 - 3, Frame torque settings) while holding the nut.

Locate service tool no. 88713.3166 On the ring nut (13) and fit the torque wrench to the tool. While holding the adjuster (14), tighten the ring nut (13) to a torque of 100 nm +/- 5% (sect. 3 - 3, Frame torque settings).

Tighten screws (11), (3) and (10) in this order to a torque of 44 nm +/- 10% (sect. 3 - 3, Frame torque settings).

Finally, tighten the screw (12) to a torque of 45 nm +/- 10% (sect. 3 - 3, Frame torque settings) while holding the nut.

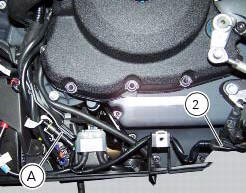

Connect connector (a) of the side stand switch to the main wiring harness.

To place the stand switch wiring refer to the table (sect. 6 - 1, Routing of wiring on frame).

Removing of the side stand

Removing of the side stand

Disconnect connector (a) of the stand switch (2) from the main wiring.

Loosen the screws (3), (10), (11) and (12) securing the stand bracket (4) to

the engine and remove the complete side

...

Frame inspection

Frame inspection

Frame

Rh subframe

Lh subframe

Grub screw

Nut

Special screw

Rubber pad

Nut

Special screw

Screw

Left-hand bracket

Hose clip

Hose clip

Right-hand bracket

Special screw

...

Other materials:

Lap registration function

This function describes the "lap" time registration.

If the function is activated (see "lap activation/deactivation

description), the lap time can be registered as follows:

Pressing the flash headlight button (11, fig. 12) The first

time starts the "lap timer" for ...

Injectors

Introduction

The injectors used on the diavel are top feed units, meaning that fuel is fed

into the top of the injector itself. The

injectors contain a winding which raises a needle when electrically energised.

This opens the atomiser nozzle, through

which pressurised fuel is dispensed, gener ...

Replacing the front phonic wheel sensor

Disconnect the front abs sensor (2) connector (a) from the main electric

wiring.

Open all the retainer clamps of the front abs sensor cable (2): refer to table

of sect. 7 - 6, Flexible wiring/hoses

positioning.

Loosen retaining screw (1) and remove the front abs sensor (2) with

ca ...