Ducati Diavel Service Manual: Refitting the timing belt driveshaft pulleys

To fit the circlip (10) in the driveshaft seat, use the tool code 88713.2834.

Install the inner spacer (17) on the driveshaft, taking care to align the notch in the spacer with the slot for the woodruff key.

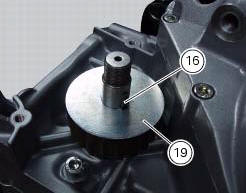

Fit the first woodruff key (16) on the timing belt driveshaft.

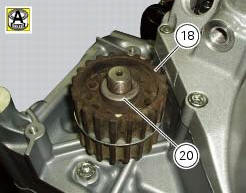

Locate the inner pulley (18).

Refit the second tongue (16) and the washer (19).

Locate the outer pulley (18) and the spacer (20).

Apply the recommended grease to the threads on the end of the driveshaft.

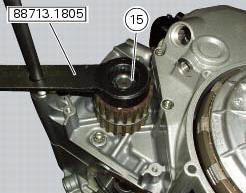

Fit the nut (15).

Important

To prevent the nuts working loose and consequent serious engine damage, always use new self-locking nuts on all the timing belt pulleys on reassembly.

Lock rotation of the pulleys by means of the tool part no. 88713.1805 And, using the insert supplied with the wrench together with a torque wrench, tighten the self-locking nut to the torque of 71 nm (min. 64 Nm - max. 78 Nm) (sect. 3 - 3, Engine torque settings).

Removing the timing belt driveshaft pulleys

Removing the timing belt driveshaft pulleys

Use the tool code 88713.1805 To hold the driving pulley on the engine

crankcase against rotation.

Important

If this operation is carried out with the engine installed in the frame,

hold the driv ...

Refitting the idler and tensioner pulley mounting studs

Refitting the idler and tensioner pulley mounting studs

Apply the recommended threadlocker to the threads of the studs.

Insert the tensioner pins (12) on the cylinder heads, and tighten them using the

tool code 88713.1821.

Tighten the tensioner pin ...

Other materials:

Removal of the control unit

Loosen the screws (1) and remove the relay supporting bracket (2), disconnect

the connectors (3) and remove the control

unit (4) from the vehicle.

...

Battery voltage indicator (battery)

This function describes the battery voltage indicator.

To access the function it is necessary to view the "setting" menu page 48, using

button (1, fig. 14) ?"" or (2, fig.

14) ?" " select the "battery" function

and press the reset

button (12, fig. 12 ...

Electric system

Basic electric items are:

headlight:

low beam bulb type: 1xh7 blue vision (12v-55w);

high beam bulb type: 1xh1 (12v-55w);

parking light: led (12v-2.4W).

Electrical controls on handlebars.

Turn indicators:

front: led (13.5V-2.9W).

Horn.

Brake light switches.

Sealed battery, 12v-10 ...