Ducati Diavel Service Manual: Removal of the evaporative emissions canister

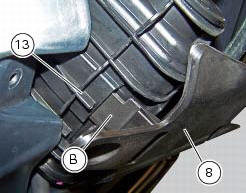

Loosen the screws (9) securing the plate (8) to the tank.

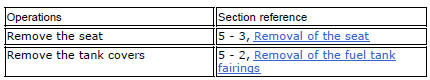

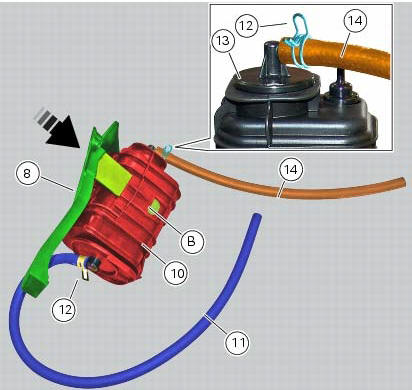

Slightly pull the plate (8) with the canister (13), remove the clamps (3) and (12) and connect hoses (7) and (14).

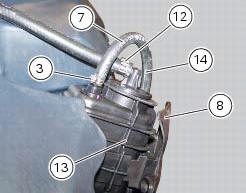

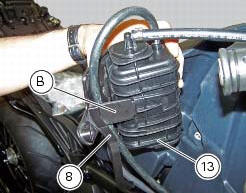

Release the retainers (b) of the plate (8) to remove it from the canister (13).

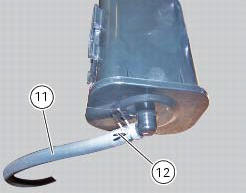

Disconnect the hose (11), removing the clamp (12).

Should it be necessary to replace one or more hoses, follow the procedure outlined in the paragraph "positioning the hoses / clamps and canister filter" of this section to determine the hose routing on the vehicle.

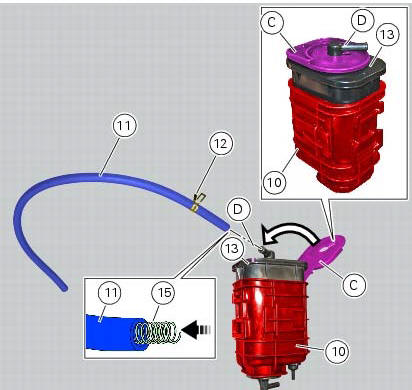

If removed, refit the rubber cover (10) on canister (13) using lubricant specific for rubber.

Fix cover (10) by positioning the tab (c) as indicated.

Introduce the spring (15) inside the hose (11) and reinsert the hose on fitting (d).

Note

The spring (15) must be introduced on the side of hose (11) which will be introduced inside the fitting (d).

Fix the hose (11) with the clamp (12).

Fit the clamp (7) on the hose (14).

Mount the hose (14) on the upper fitting of the canister (13) and fix the hose (14) by means of the clamp (7).

Fit the plate (8) as indicated by inserting its lateral brackets (b) (on the right and left side) completely inside the slots on the rubber cover (10).

Note

In case of difficulties upon reassembly of the plate (8) we recommend to apply lubricant specific for rubber to the lateral brackets (b).

Place the plate (8) with the relevant canister on the tank and tighten the screws (9) to a torque of 4 nm +/- 10% (sect. 3 - 3, Frame torque settings).

Evaporative emissions canister system (usa versions only)

Evaporative emissions canister system (usa versions only)

Usa models are equipped with an additional system with an evaporative

emissions canister that prevents fuel fumes from

being discharged into the atmosphere.

The breather hose (4) is connected to t ...

Refitting the evaporative emissions canister

Refitting the evaporative emissions canister

To refit, carry out the removal operations in reverse order, making sure to

locate the hoses as shown in the figures at the

end of the chapter.

Positioning the hoses / clamps and canister filt ...

Other materials:

Throttle valve actuator motor relay

Introduction

The throttle valve actuator motor is powered by the engine control unit. The

engine control unit receives the necessary

power from a specific relay.

Component assembling position

A injection relay; b etv relay (throttle valve actuator motor), c radiator

fan relay, d engine c ...

Removal of the crankshaft/connecting rods assembly

After separating the crankcase halves, withdraw the crankshaft (6) complete

with connecting rods (2).

...

Refitting the handlebar

Position the handlebar (4) so that the external lower corner of the marks (a)

on the handlebar matches the upper internal

corner of the lower u-bolts (b) as shown.

Apply the recommended grease to the threads and undersides of the heads of

the screws (3).

Important

Position the upper u-bo ...