Ducati Diavel Service Manual: Removal of the gear selector lever

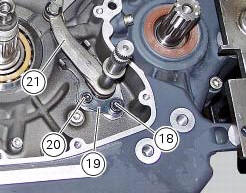

Unscrew and remove the fixing screws (18) and (20) of the complete gear selector lever (21) and collect the spacer (19).

Remove the gearchange mechanism complete with the shaft, spring, and stop plate.

Important

Visually inspect the gear selector claw (14) for wear, particularly around the area where it contacts the selector drum.

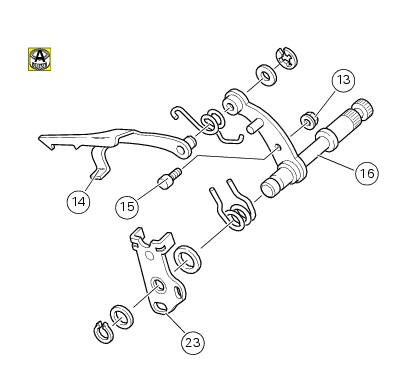

If it proves necessary to change components, disassemble the gear selector lever as shown in the exploded view.

Reassemble the gear selector lever orienting the eccentric pin (15), suitably lubricated, in such a way that the lever arm (16) is positioned centrally with respect to the shoulders of the stop plate (23).

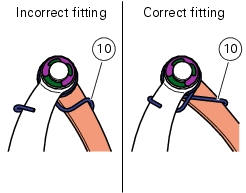

Check that the spring (10) is installed correctly as shown in the figure.

Tighten the nut (13) to a torque of 10 nm (min. 9 Nm - max. 11 Nm) (sect. 3 - 3, Engine torque settings).

Gearchange mechanism

Gearchange mechanism

Return spring

Washer

Special screw

Gear pawl assembly

Interlock plunger holder

Sealing washer

Detent ball spring

Ball

Circlip

Selector claw return spring

Shim washer

Ring

...

Disassembly of gear interlock plunger and pawl assembly

Disassembly of gear interlock plunger and pawl assembly

Unscrew the interlock plunger screw (5) and remove the seal (6), spring (7)

and the detent ball (8).

Unscrew the clutch-side crankcase half screw (3) and remove the pawl (4),

washer (2) a ...

Other materials:

Operating principle and characteristics of the ride-by-wire system

The engine control system of the diavel uses a ride-by-wire system with

motorised throttle valves. This eliminates all

direct connection with metal cables between the throttle grip and the throttle

valves themselves. Cables are used to

rotate the aps potentiometer, which generates an electric ...

Vehicle pre-delivery

Transport packaging integrity check (if required);

Removal from the transport packaging (if required);

Motorcycle integrity check;

Check of the supplied kit completeness (refer to the parts list supplied

together with the bike packaging);

Only if the bike is supplied in a crate: handle ...

Refitting the rear wheel

Lubricate the wheel shaft threaded end with prescribed grease.

Insert the wheel shaft by matching (a) with pins (b).

Install spacer (3) with the conical surface faced to the wheel conical

surface, washer (2), apply prescribed grease to nut

(1) and insert it by hand (1).

Tighten the ...