Ducati Diavel Service Manual: Removal of the rear brake calliper

Important

The brake manufacturer advises against any servicing of the internal components of brake callipers or the master cylinder.

Incorrect overhaul of these critical safety components can endanger rider and passenger safety.

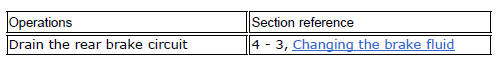

Before removing the parts in question, you must first carry out the following operations:

note

For the abs front braking system, also refer to sect. 7 - 5, Abs system operating information, sect. 7 - 6, System components, sect. 7 - 7, Abs components maintenance.

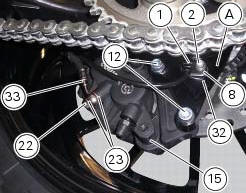

Unscrew and remove the special screw (22) fixing the pipes (33) to the rear brake calliper and the corresponding couplings (23).

Remove tube (33).

Undo the two fixing screws (12) of the rear brake calliper (15) to the calliper holder bracket and remove the brake calliper (15).

If it is necessary to remove the calliper holder bracket (a) refer to sec. 7 - 13, Removal of the rear wheel eccentric hub and rear wheel shaft.

Note

To replace the brake pads follow instructions in the paragraph "checking brake pad wear and changing brake pads" (sec. 4 - 3).

To remove the speed sensor (1), undo the retaining screw (2), having care not to damage the airgap spacer (8) and the washer (32).

Only the following parts should be renewed:

- Brake calliper: pads, fasteners and bleed valve assembly;

- Master cylinder: control pedal, bleed valve assembly, reservoir and its components.

Refer to the exploded view at the beginning of this section for indications on renewal of the above components.

Refitting the rear brake control

Refitting the rear brake control

If the pushrod (18), clip (30) and fork (31) assembly has been dismantled,

reassemble it by screwing the nut (29) onto

the rod (18) and then screw the rod into the fork (31) to obtain the measureme ...

Removal of the rear brake disc

Removal of the rear brake disc

Remove the rear eccentric hub (sec. 7 - 13, Removal of the rear wheel

eccentric hub and rear wheel shaft).

Undo and remove the four fixing screws (13) of the brake disk to the wheel axle

and re ...

Other materials:

Refitting the external components

Fit the cap (39) on spring (38) until it engages.

Mount ball (40), spring (38) with cap (39), washer (37) and screw (36) on the

chain side half-casing by starting the

screw into hole (f).

Note

The spring (38), with cap (39), must be oriented as shown.

Tighten the screw fully home to a torqu ...

Tips on how to select the sensitivity level

Warning

The 8 level settings of the dtc were calibrated using tyres of the

same make, model and size as those originally fitted to

the motorcycle.

The use of tyres of different size to the original tyres may alter the operating

characteristics of the system.

In the case of minor differen ...

Operating principle of dtc

The bbs receives the front and rear speed information from the abs over the

can. Then, the bbs sends the vehicle speed

information to be displayed on the dashboard over the can.

If the tangential speed of the rear wheel exceeds the tangential speed of the

front wheel by a given percentage, t ...