Ducati Diavel Service Manual: Removal of the rear brake disc

Remove the rear eccentric hub (sec. 7 - 13, Removal of the rear wheel eccentric hub and rear wheel shaft).

Undo and remove the four fixing screws (13) of the brake disk to the wheel axle and remove the rear brake disk (14).

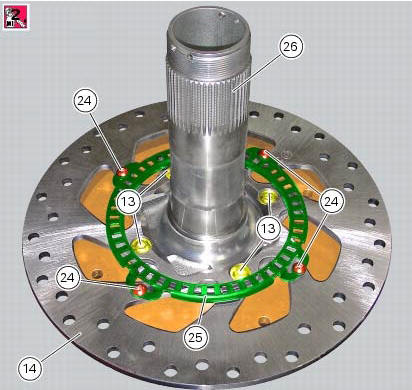

Loosen the four screws (24) and remove the rear phonic wheel (25).

The brake disc must be perfectly clean, with no rust, oil, grease or other dirt and no deep scoring.

To check the wear limit of the brake disk refer to sec. 3 - 1.1, Hydraulic brakes.

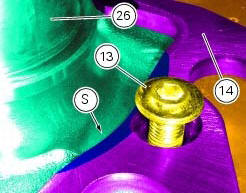

Place the rear brake disc (14) on the rear wheel shaft (26), by orienting the bevelled edges (s) faced upwards.

Fix the disc by starting the screws (13) with prescribed threadlocker.

Note

Make sure to centre the screw heads in the relevant seats on the brake discs.

Tighten the screws (13) to a torque of 27 nm +/- 10% (sect. 3 - 3, Frame torque settings), in the sequence 1-2-3-4.

Position the phonic wheel (25) on the brake disc (14) by orienting it as shown in figure.

Fix the phonic wheel (25) by starting the screws (24) with the recommended threadlocker.

Tighten the screws (24) to a torque of 5 nm +/- 10% in a crossed-pattern sequence.

Refit the rear eccentric hub as described in sec. 7 - 13, Removal of the rear wheel eccentric hub and rear wheel shaft.

Removal of the rear brake calliper

Removal of the rear brake calliper

Important

The brake manufacturer advises against any servicing of the internal

components of brake callipers or the master cylinder.

Incorrect overhaul of these critical safety components can en ...

Refitting the rear brake calliper

Refitting the rear brake calliper

When replacing the brake pipes (33) or removing one of the rear braking

system components, pay special attention to the

position of the couplings on the pump and the calliper.

Warning

If incorrec ...

Other materials:

Injection and ignition

Introduction

Ignition is via a single stick coil per cylinder installed in the spark plug

well. Each thermal unit is supplied by a single

injector, placed under the throttle valve. The amount of fuel injected and the

ignition advances are determined by the

control unit specifically for each c ...

Clutch cover

Clutch-side crankcase cover

Screw

Screw

Oil level sight glass

Screw

Plate

Bush

Sealing ring

Shim washer

Circlip

O-ring

Locating bush

O-ring

Plug

Sealing washer

Screw

Plug

Panel

Spare parts catalogue

Diavel abs clutch-side crankcase cover

Diavel carbon

a ...

Reassembling the electrical components support

Check the presence of clips (1), (9) and (24) on the support (5).

Check the presence of rubber pads (6) and (8) and of cable grommet (7).

Check that the voltage regulator (3) and the solenoid starter (18) are in

place on the support (5) with their wiring as

shown.

The horn (22) mus ...