Ducati Diavel Service Manual: Removal of the swingarm

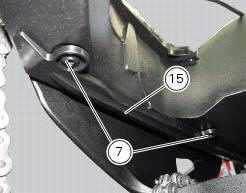

Before removing the parts in question, you must first carry out the following operations:

Remove the rear wheel eccentric hub as described in chapter "removal of the rear wheel eccentric hub and rear wheel shaft" of this section.

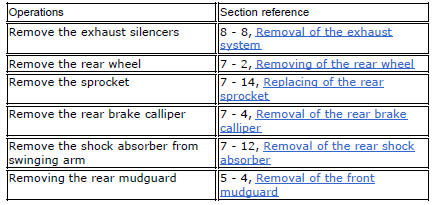

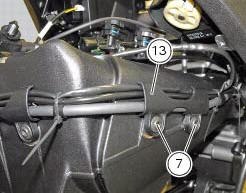

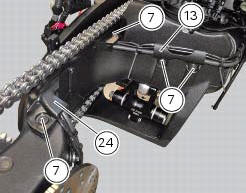

Loosen screws (7) and remove the hose grommets (13), (15) and (24).

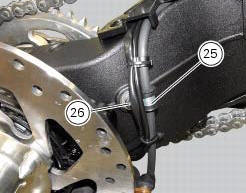

Release the rear brake hose, the rear speed sensor cable, and the rear wiring from the swingarm, by loosening the screws (26) and retrieving the cable grommets (25).

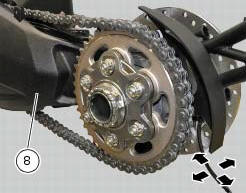

You can check the play in the swingarm bearings while the swingarm (8) still installed on the motorcycle frame.

Grasp the rear of the swingarm (8) and try to move it in the four directions shown by the arrows.

Any abnormal movement is a sign of worn bearings that could cause instability when riding.

To check the free play of the support bearings, refer to sect. 7 - 1, Wheel bearings.

Once the play in the swingarm bearings has been checked, the swingarm (8) may be removed from the motorcycle.

Keep the swingarm shaft (1) blocked with the screws (3) on the bike lh side and loosen at the same time the screw (3) on the opposite side: keep washer (2).

Using the punch 88713.1074, Fully extract the swingarm pivot.

Remove the swingarm (8) assembly from the frame.

Inspecting the swingarm pivot

Before refitting the swingarm pivot shaft (1), check it carefully for distortion.

Roll the pin on a reference surface and measure maximum distortion using a feeler gauge (sect. 3 - 1.1, Rear wheel).

Refitting the rear wheel eccentric hub and rear wheel shaft

Refitting the rear wheel eccentric hub and rear wheel shaft

Refitting is the reverse of removal, with attention to the following points.

If the calliper bracket locating pin (14) was removed, apply the recommended

threadlocker on reassembly.

Tighten th ...

Overhauling the rear swingarm

Overhauling the rear swingarm

Inside the swingarm (8), in correspondence with the pivot point on the frame,

there is a pair of ball bearings (10) and a

spacer (11) on the rh side, and a pair of roller bearings (6), with sealing ...

Other materials:

Refitting the gear interlock plunger and pawl assembly

On the special screw (3), fit the gear pawl lever (4), orienting it as shown

in the figure, the washer (2) with the square

edge side (d) facing the clutch-side crankcase half, and the spring (1),

positioning it so that the hook end (a) is facing

the gear pawl lever. Locate the hook end (a) of ...

Engaged gear indicator

This function displays the gears (1, fig. 25).

The instrument panel receives information and indicates the

engaged gear or "n" for neutral.

Note

In the case of a gear sensor "error", a dash "-" (not

flashing) will be displayed.

...

Removal of the handlebar

Unscrew and remove the screws (3) securing the upper clamp (1).

Remove the upper clamp (1).

Remove the handlebar (4) from its seat on the steering head.

To remove the grips (5), refer to the exploded view at the beginning of this

chapter.

...