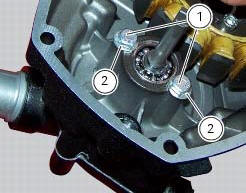

Ducati Diavel Service Manual: Removal of the water pump

Note

For clarity, the figures show the engine removed from the frame.

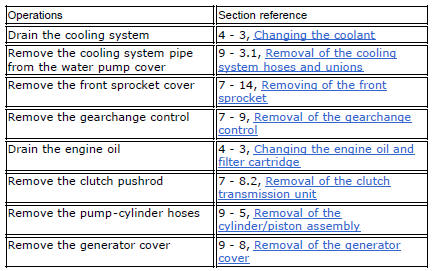

Loosen and remove the water pump cover (12) fixing screws (13) to the generator cover (16).

Remove the water pump cover (12).

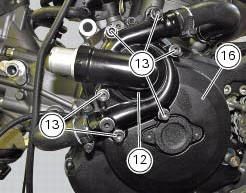

Clean the pump housing of any scale. Check the bearings wear by turning the impeller shaft (10); in case of excessive clearance, it is necessary to replace them by operating as follows.

Remove the circlip (3) on the impeller shaft.

Slide off the rotor (10) with the sealing ring (9) from the outside.

Recover the ceramic washer - seal unit (8) placed on the internal side.

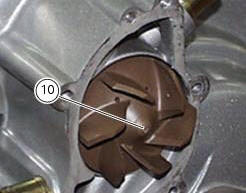

Undo and remove the screws (1) with the washer (2).

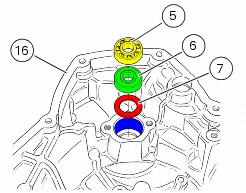

Working from the generator cover (16) internal side, use a suitable punch to press on the inner race of end bearing (5) until it can be extracted from the cover.

Use the same technique to remove the other bearing (6).

Remove the inner spacer (7).

Check the condition of the components of the mechanical seal: there should be no signs of deformation, cracking, or excessive wear. In the case of damage, both components must be renewed.

Water pump

Water pump

Screw

Washer

Circlip

Water pump outlet union

Bearing

bearing

Spacer

Aluminium gasket

Mechanical seal

Water pump impeller

Bush

Water pump cover assembly

Screw

Plug

Se ...

Refitting the water pump

Refitting the water pump

Clean the seat on the cover, any parts you intend to reuse, and the impeller

shaft. Then refit as follows.

Fit on the impeller (10) shaft the mechanical seal (9) as indicated in the

figure.

...

Other materials:

Reassembly of the connecting rods

Before starting, check that the crankshaft main bearing journals and big-end

journals are free of burrs or evident signs of

machining: if necessary, clean the surfaces with very fine emery cloth and oil.

Check that the grooves are in perfect condition with no signs of forcing.

Clean the cra ...

Abs fault indicator not working

Fault codes

Dds: displays a fault code described in the description of the abs system.

Dashboard: no fault code displayed.

Wiring diagram

Checks

The abs fault indicator indicates the occurrence of one or more faults in the

antilock brake system, or if the system itself

has been disable ...

Adjusting the position of the gearchange and rear brake

pedals

The position of the gearchange and rear brake pedals in

relation to the footrests can be adjusted to suit the

requirements of the rider.

Adjust the pedals as follows:

Gear change pedal (fig. 97)

Hold the linkage (1) and slacken the lock nuts (2) and (3).

Note

Nut (2) has a left-hand thr ...