Ducati Diavel Service Manual: Removing of the front sprocket

Undo the screws (11) and remove the chain cover (10).

Loosen the chain (sect. 4 - 3, Adjusting the chain tension).

Remove the chain with the tool code 88713.1344.

The tool is composed of a holder (a), punch (b), body (c) and two wrenches (d) and (e).

Fit the link to be opened into the holder (a).

Fit a punch (b) into the body (c) and manually unscrew the screw until the punch no longer protrudes.

Fit the holder (a) and link into the body (c).

Manually turn the screw (f) on body (c) so that the punch (b) locates against the pin, taking care that they are aligned with each other.

Fit hex wrench (d) into the hexagonal part of the body (c) and wrench (e) onto the bolt.

Turn the bolt (f) clockwise to push out the pin.

Remove the chain.

Engage a low gear and unscrew the nut (12).

Remove the nut (12) and the safety washer (13) on the pinion.

Remove the engine pinion (14) from the gearbox secondary shaft.

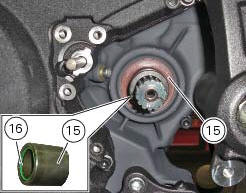

Remove the spacer (15) with o-ring (16) from the gearbox secondary shaft.

Important

The o-ring (16) must be renewed on reassembly.

Inspecting the final drive

Inspecting the final drive

To check the wear of the final drive, visually check the pinion (14) and

sprocket (17). If the teeth are found to worn as

shown in the figure (dotted line), the sprocket must be renewed.

T ...

Refitting the front sprocket

Refitting the front sprocket

Grease the o-ring (16) and install it on the front sprocket spacer (15).

Fit the spacer, from the o-ring side, on the secondary shaft and drive it fully

home against the inner ring of the bearing ...

Other materials:

Refitting the clutch-side crankcase cover

Clean and degrease mating surfaces on the clutch-side crankcase half cover

and crankcase and ensure that locating bush

(12) and the o-ring (11), located in correspondence with the oil way, are

installed in the crankcase.

Apply an even, regular bead of ducati liquid gasket (a) on the mating ...

Disassembly of gear interlock plunger and pawl assembly

Unscrew the interlock plunger screw (5) and remove the seal (6), spring (7)

and the detent ball (8).

Unscrew the clutch-side crankcase half screw (3) and remove the pawl (4),

washer (2) and spring (1).

...

Refitting the number plate holder

Place the number plate light (5), as indicated, on the number plate holder

plate (8) and tighten the screws (7) to a torque

of 2 nm +/- 10% (sect. 3 - 3, Frame torque settings).

Thread the number plate light wiring (c) into the opening in the number plate

holder plate as shown.

Fit ...