Ducati Diavel Service Manual: Removing the electrical components support

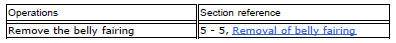

Remove the following elements located inside the electrical components support:

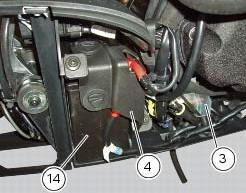

- The battery fixing bracket (4) and the battery (14) as specified under section 6 - 2, battery;

- The voltage regulator (3) as specified under section 6 - 2,rectifier-regulator;

- The solenoid starter (18) as specified under section 6 - 3,solenoid starter;

Remove the connector (a) of horn (22) from the main wiring.

Undo the screw (25) and remove the horn (22) from the vehicle.

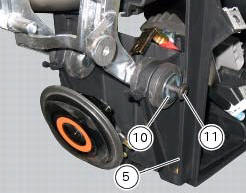

Loosen screws (11) and (21) and recover the washer (10) and the spacer (20).

Remove the electrical components support (5).

Pay attention to the main wiring branch and to any other wiring inside of it.

Refer to the tables reported in this section for the components position.

Electrical components support

Electrical components support

Clip

Screw

Voltage regulator

Battery fixing bracket

Battery support

Vibration damper mount

Hose clip

Vibration damper mount

Clip

Washer

Screw

Cover

Cable grommet

Batte ...

Reassembling the electrical components support

Reassembling the electrical components support

Check the presence of clips (1), (9) and (24) on the support (5).

Check the presence of rubber pads (6) and (8) and of cable grommet (7).

Check that the voltage regulator (3) and the solenoi ...

Other materials:

Removal of the lubrication system

Disconnect the sensor (12) of the main wiring.

Open the pipe grommet (11).

Undo the screw (8) and slide out the plate (9).

Slide the tubes (7) out of the half-casing having care not to damage the tubes

o-rings (a) that guarantee the coupling

sealing.

Undo and remove the sc ...

Lap registration function

This function describes the "lap" time registration.

If the function is activated (see "lap activation/deactivation

description), the lap time can be registered as follows:

Pressing the flash headlight button (11, fig. 12) The first

time starts the "lap timer" for ...

Pre-ride checks

Warning

failure to carry out these checks before riding, may

lead to motorcycle damage and injury to rider and passenger.

Before riding, perform a thorough check-up on your bike as

follows:

Fuel level in the tank

Check the fuel level in the tank. Fill tank if needed (page 140).

Engine oil le ...