Ducati Diavel Service Manual: Removing the valve rocker arms

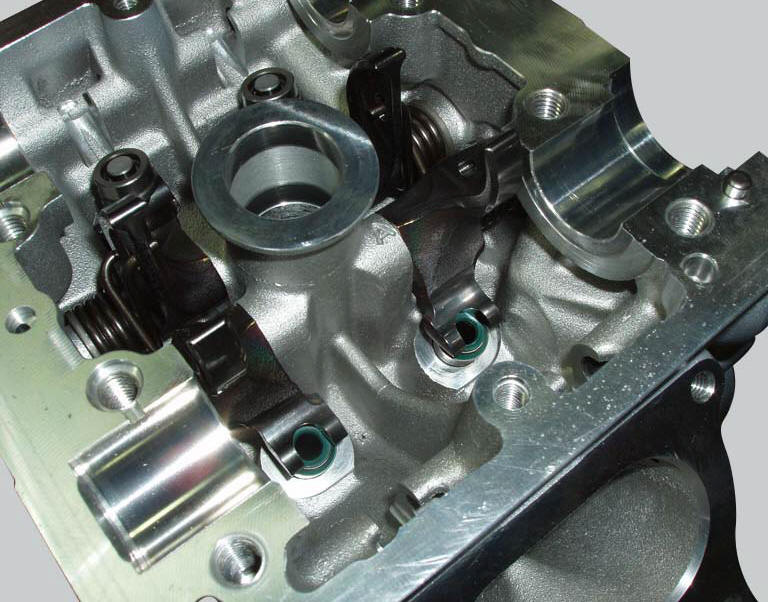

With the cylinder head in the condition described in the previous paragraph, remove the rocker arms.

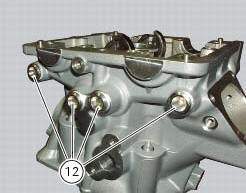

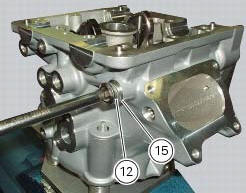

Unscrew the eight plugs (12) and recover the seals (15).

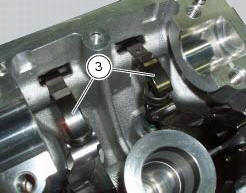

Using an m6 screw, withdraw the shafts (2) of the opening rocker arms (3) on the exhaust and intake sides.

Remove the opening rocker arms (3).

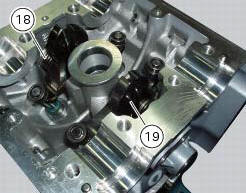

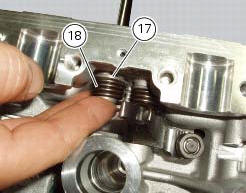

Using the claw of the rocker arm spring tensioning kit 88713.2069 Installed between the spring and the inner wall of the cylinder head, move the straight end of the rocker arm return spring (19) and (18) and insert it in the drilled shaft.

Use the shaft to slide the end of the spring into its final position.

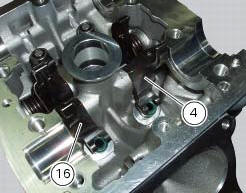

Using an m6 screw, withdraw the shafts (1) of the closing rocker arms on the exhaust and intake sides.

Remove the closing rocker arms (4) and (16), the springs (18) and (19) with the spacers (17).

Carry out the same operation to remove the closing rocker arms (4) and (16), the springs (24) and (25) with the spacers (23).

Remove the sealing rings (8) from the ends of the valve guides.

Repeat the same procedure for the other cylinder head.

Removing the valves

Removing the valves

Raise the rocker arm (3) and remove the opening shim (5) from the valves with

a pair of pliers.

Push down the closing rocker arms (16) and (4) and the closing shim (7).

Remove the half r ...

Overhaul of cylinder head components

Overhaul of cylinder head components

Cylinder heads

Remove any carbon deposits from the combustion chamber and its ducts.

Remove any scale from the coolant ducts.

Check for cracking and inspect the sealing surfaces for scoring, ri ...

Other materials:

Indicator air - air temperature

This function shows the external temperature.

Display limits: -39C ÷ +124C

In the event of a sensor fault (-40C,+125C or

disconnected), a string of dashes "- - -" (not flashing) is

displayed and the "engine/vehicle diagnosis - eobd" light

(7, fig. 4) Comes on.

N ...

Fairings

Rh front half-fairing

Clip

Screw

Right-hand support

Screw

Screw

Rh air inlet

Lh air inlet

Screw

Clip

Left-hand support

Lh front half-fairing

Lh tank fairing

Screw

Nylon washer

Special screw

Washer

Spacer

Spring

Rubber pad

Rh tank fairing

Tank fairing

...

Adjusting the rear shock absorber

The rear shock absorber has external commands that enable

you to adjust the setting to suit the load on the motorcycle.

The adjuster (1, fig. 111) Located on the lower connection

holding the shock absorber to the swingarm adjusts the

damping during the rebound phase (return).

The knob (2, f ...