Ducati Diavel Service Manual: Renewal of the headlight

Disconnect the headlight connectors (a) from the main wiring (refer to the tables of paragraph "routing of wiring on frame", sect. 6 - 1).

Loosen nuts (2) that fix the front optical unit to the bottom yoke, and recover the washers (3).

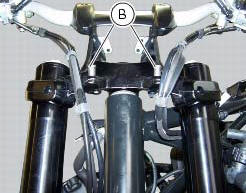

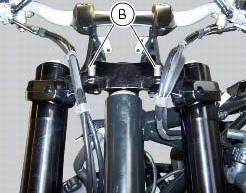

Remove the complete front optical unit by sliding it upwards and releasing it from pins (b) of the supporting bracket.

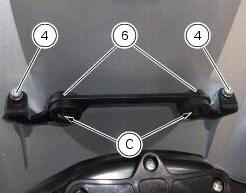

Release the headlight from the front optical unit support by loosening the screws (4) and recovering the washers (5).

Refit the headlight on the front optical unit support, insert the spacers with collars (5) and the screws (4).

Apply the recommended threadlocker to the screws (4).

Tighten the screws (4) to a torque of 6 nm +/- 10% (sect. 3 - 3, Frame torque settings).

Check for the pads (6) on the supporting bracket.

Apply the recommended threadlocker to the screws (4).

Tighten the screws (4) to a torque of 6 nm +/- 10% (sect. 3 - 3, Frame torque settings).

Refit the front optical unit by placing its lower part on the pads (d) and inserting the pins (b) into the eyelets (c) of the supporting bracket.

Fix the front optical applying a torque of 10 nm +/- 10% (sect. 3 - 3, Frame torque settings) to the nuts (2) with washers (3).

Reconnect the headlight connectors (a) to the main wiring (refer to the tables of paragraph "routing of wiring on frame", sect. 6 - 1).

Changing bulbs

Changing bulbs

Changing the headlight bulbs

Before replacing a burnt out light bulb, ensure that the replacement bulb has

the same voltage and power rating as

specified for the lighting device in question (sect. ...

Other materials:

Ground connection locations

The negative cable, which is normally connected to the negative pole of the

battery, is fastened to the crankcase. From here, the cable

branches off and splits up within the electrical system to carry the ground

connection to the different elements in the system.

The image shows the ground ...

Refuelling

Never overfill the tank when refuelling. The fuel level should

always be below the rim of the filler recess.

Warning

Use low-lead fuel with 95 octane rating at origin

minimum (see "top-ups" table, page 173).

Check that no fuel is trapped in the filler cap recess.

...

Indicator cons. Avg - average fuel consumption

This function indicates the "average" fuel consumption.

The calculation is made considering the quantity of fuel used and the km

travelled since the last trip 1 reset. When trip 1

is reset, the value is set to zero and the first available value is shown on the

display 10 seconds after the re ...