Ducati Diavel Service Manual: Replacing the rear phonic wheel sensor

Disconnect the rear abs sensor (5) connector (c) from the main electric wiring.

Open all the retainer clamps of the rear abs sensor cable (5): refer to table of sect. 7 - 6, Flexible wiring/hoses positioning.

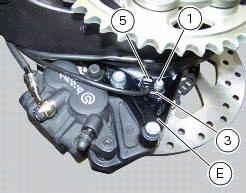

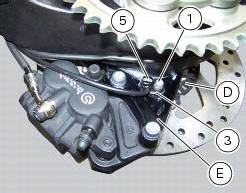

Remove the rear abs sensor (5) from its seat on the rear calliper mounting bracket (e), undoing the retaining screw (1) and collect the calibrated gasket (3).

Before refitting, make sure that the contact parts between the rear abs sensor (5) and its seat are not damaged and are perfectly clean.

Fit the new rear abs sensor (5) on its seat inserting the screw (1).

Check the air gap between the new rear abs sensor (5) and the rear phonic wheel (d) as indicated in sect. 7 - 7, Adjusting of the air-gap phonic wheel sensor.

Fix the sensor to the calliper holder bracket tightening the screw (1) to a torque of 10 nm +/- 10% (sect. 3 - 3, Frame torque settings).

Connect the connector (c) to the main wiring.

Restore all the retainer clamps of the rear abs sensor cable (5): refer to table of sect. 7 - 6, Flexible wiring/hoses positioning.

Replacing the front phonic wheel sensor

Replacing the front phonic wheel sensor

Disconnect the front abs sensor (2) connector (a) from the main electric

wiring.

Open all the retainer clamps of the front abs sensor cable (2): refer to table

of sect. 7 - 6, Flexible wiri ...

Removing of the abs control unit

Removing of the abs control unit

Drain the hydraulic fluid that is inside the front and rear braking system

tubes by disconnecting them from the master

cylinder and the calliper (sect. 4 -3, Changing the brake fluid).

Disco ...

Other materials:

Refitting the camshafts

If the stud bolts (2) were removed, apply the recommended threadlocker to the

short end of the stud bolts (2), i.E. The

end that is to be screwed into the cylinder head. Tighten the stud bolts (2) to

a torque of 10 nm (min. 9 Nm - max. 11

Nm) (sect. 3 - 3, Engine torque settings).

Check t ...

Reassembly of rear shock absorber - rocker arm - linkage assembly

Once the needle roller bearings (9) have been removed from the rocker arm

(18), upon reassembly fit a new needle roller

bearing (9) on drift part no. 88713.1071 And lubricate with recommended grease.

Support the rocker arm and drive the needle roller bearings into the rocker arm

bore until t ...

Engine on/off

Warning

Before starting the engine, become familiar with the

controls you will need to use when riding (page 99).

Warning

Never start or run the engine indoors. Exhaust gases

are toxic and may lead to loss of consciousness or even

death within a short time.

In the presence of the active or ...