Ducati Diavel Owners Manual: Running-in recommendations

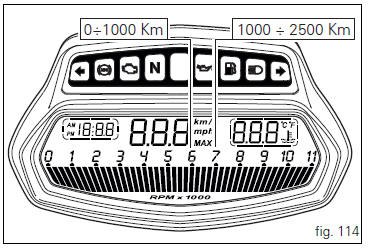

Maximum rpm (fig. 114)

Rotation speed for running-in period and during standard use (rpm)

- Up to 1000 km;

- From 1000 to 2500 km.

Up to 1000 km

During the first 1000 km, keep an eye on the rev counter.

It should never exceed 5500÷6000 rpm.

During the first hours of riding, it is advisable to run the engine at varying load and rpm, though still within recommended limit.

To this end, roads with plenty of bends and even slightly hilly areas are ideal for a most efficient running-in of engine, brakes and suspension.

For the first 100 km use the brakes gently. Avoid sudden or prolonged braking. This will allow the friction material on the brake pads to bed in against the brake discs.

To allow all the mechanical moving parts in the motorcycle to adapt to one another, and to avoid shortening the life of the main engine components, it is advisable to avoid sudden acceleration and running the engine at high rpm for too long, especially uphill.

Furthermore, the drive chain should be inspected frequently.

Lubricate as required.

From 1000 to 2500 km

At this point, you can squeeze some more power out of your engine. However never exceed 7000 rpm.

Important

Important

Throughout the running-in period, be careful to stick to the recommended maintenance schedule and periodic service intervals indicated in the warranty booklet. Failure to follow these instructions releases ducati motor holding s.P.A. From any liability whatsoever for any engine damage or shorter engine life

Strict observance of running-in recommendations will ensure longer engine life and reduce the likelihood of overhauls and tune-ups.

Pre-ride checks

Pre-ride checks

Warning

failure to carry out these checks before riding, may

lead to motorcycle damage and injury to rider and passenger.

Before riding, perform a thorough check-up on your bike as

follows:

Fuel ...

Other materials:

Vehicle speed indicator

this function displays vehicle speed (km/h or mph

depending on the set measurement system).

the instrument panel receives information about the actual

speed and displays the number increased by 5%.

maximum speed displayed is 299 km/h (186 mph).

over 299 km/h (186 mph) a series of dashes w ...

Removal of the steering head components

Note

All parts fitted to the top and bottom yokes, including the wiring and

control cables, can remain on the motorcycle

provided they do not hinder the following operations.

Loosen the screws (19) securing the supports (21) and (23) of splashguard

(22) to the air conveyors (t).

...

Removal of the camshafts

Unscrew and remove the screws (7) and the o-rings (8) from the cylinder head

covers.

Remove the cylinder head cover (6).

Remove the gaskets (4) and (9).

Repeat the same procedure for the other cylinder head cover. Unscrew the

screws (3) securing the camshaft supports.

Withdra ...