Ducati Diavel Service Manual: Running lights not working

Fault codes

Dds: no fault code displayed.

Dashboard: no fault code displayed.

Location of connections and components

(A) low / high beam and parking light connections rear running light and stop light connection.

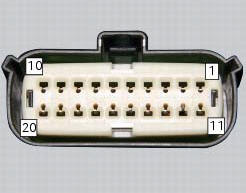

Pin numbering of wiring harness side bbs unit connection.

Checks

The front and rear parking lights use led light units and receive a 12 v power supply. Power the parking lights with an external 12 v power supply to test function (connect correctly as indicated in the wiring diagram).

Check congruence of the ground connection on the running lights.

Check that the parking lights receive 12v arriving from pin 7 of the bbs.

Check the integrity of the electrical circuit and connections (short-circuits to ground, short-circuits to vdc, open circuits).

If none of the aforementioned tests identifies the problem, replace the bbs.

Note

Check integrity of electric circuit - short-circuit to vdc = with dashboard on, using a voltmeter, a voltage is measured between the wire tested and ground.

Check integrity of electric circuit - short-circuit to ground = with the battery cables disconnected, using an ohmmeter, continuity is detected between the wire tested and ground.

Check integrity of electric circuit - open circuit = with the battery cables disconnected, using an ohmmeter, no continuity is detected between the two ends of the wire tested.

Number plate light not working

Number plate light not working

Fault codes

Dds: no fault code displayed.

Dashboard: no fault code displayed.

Location of connections and components

Location of rear turn indicator and number plate light connection.

p ...

Dashboard menu option scrolling not possible

Dashboard menu option scrolling not possible

Fault codes

Dds: no fault code displayed

Dashboard: no fault code displayed

Location of connections and components

Location of left hand handlebar switchgear set connection.

Pin numbering ...

Other materials:

Removing outer components

Note

The following removal operations are required in order to renew and/or

clean the crankcase halves. If the original

crankcase halves are to be reused, then the removal of these components is not

essential.

Unscrew the screw (17) and remove the oil breather valve (1) with the o-rings

...

Riding mode customisation

This function customises each riding style.

To access the function it is necessary to view the "setting"

menu page 48, using button (1, fig. 14) ?

or (2, fig. 14)

? select the "riding mode" function

and press the

reset button (12, fig. 12) To go to next page.

W ...

Adjusting throttle control free play

The throttle twistgrip must have free play of 1.5×2.0 Mm in

all steering positions, measured on the outer edge of the

twistgrip. If necessary, adjust it using the adjusters (1 and 2,

fig. 135) Located on the headstock on the right-hand side of

the vehicle.

Adjuster (1) is for throttle o ...