Ducati Diavel Service Manual: Shimming the shafts

Before assembling the crankcase halves, calculate the shims required to obtain the correct end float of the crankshaft and gearbox shafts.

To determine the correct shim thickness proceed as follows.

Shimming the crankshaft

- After having installed the new main bearings (with bushing (a) or flanged bearings (b)) proceed as follows to determine the total "sa" height of the shimming:

- Measure the distance "la" between the bearing contact surfaces on the crankshaft;

- Measure the depths "la1" and "la2" corresponding to the distance between contact surface of the crankcase half and the contact surface of the inner race of the bearings.

Add 0.30 Mm preload for crankshaft axial bearings to bed in correctly into their seats (inner rings seated inside outer ring).

Thus, we obtain: sa=la1+la2+0.30-La.

To calculate the thickness of each shim note that: sa=sa1+sa2 where "sa1" and "sa2" represent the shims for the clutch-side crankcase half 1 and the alternator-side crankcase half 2.

Considering the alignment of the shaft, this gives: sa1=la1+0.15-La/2; and finally, the second shim thickness: sa2=sa-sa1.

In addition to the above procedure, the following is a practical shimming method, providing a guide on how to calculate the crankshaft shim thickness accurately.

Install a shim of minimum thickness (1.90 Mm) on each side of the crankshaft to prevent contact between the crankshaft web and the crankcase.

Install the crankshaft and assemble the two crankcase halves.

Fit four m8 screws in the seats indicated in figure and tighten them to a torque of 19 nm (min. 17 Nm - max. 21 Nm) (sect. 3 - 3, Engine torque settings).

Place a dial gauge (c) with magnetic base on a support plate fixed to crankcase.

Bring the stylus into contact with the end of the crankshaft and set the dial gauge to zero in this position.

Place a lever (d) between crankcase and crank web of the crankshaft pushing towards dial gauge.

Note on the dial gauge the total clearance and add a preload of (0.30 Mm) plus the thickness of the shims used (1.90X2=3.8 Mm).

Divide the resulting value by two to obtain the thickness of the shim packs to be installed at either end of the crankshaft.

Note

After assembling the crankcase halves, the crankshaft should turn with some interference in the new bearings.

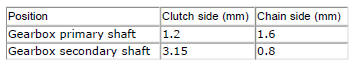

Shimming the gearbox shafts

The following thickness spacers are supplied as spare parts.

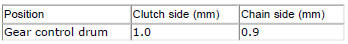

Shimming the gearbox selector drum

The following thickness spacers are supplied as spare parts.

Reassembly of the crankcase halves

Reassembly of the crankcase halves

The crankcase halves must be in good condition and perfectly clean. The

mating surfaces must be perfectly flat and free

from burrs.

Overhauling the alternator-side crankcase half

The following pa ...

Reassembly of the crankcase halves

Reassembly of the crankcase halves

If removed, apply threadlocker on the screw (36), insert it with the washer

(37) on the crankcase half and tighten it to The torque of 8 nm

(min. 7 Nm - max. 9 Nm) (sect. 3 - 3, Engine torque sett ...

Other materials:

Engine

Twin cylinder, four-stroke, 90 "l" type, longitudinal, with

deep sump die-cast crankcase.

Bore, mm: 106

Stroke, mm:

67.9

Total displacement, cu. Cm:

1198

Compression ratio:

11.5В±0.5:1

Max power at crankshaft (95/1/ec), kw/hp:

119 kw/162 hp at 9,500 rpm

Max torque at crankshaf ...

Lcd unit functions

Speedometer.

Gives road speed

Rev counter.

Indicates engine revs per minute.

Clock.

Water temperature indicator.

Indicates engine coolant temperature.

Important

Stop riding if the temperature reaches the maximum value, otherwise the

engine might be damaged.

...

Radiator fan relay

Introduction

The radiator fans are powered via a specific relay, which is enabled by the

engine control unit.

Component assembling position

A injection relay; b etv relay (throttle valve actuator motor), c radiator

fan relay, d engine control unit.

Location of right hand fan connecti ...