Ducati Diavel Service Manual: Side stand button

Introduction

The side stand button is located on the side stand. Together with the signal from the clutch button and the neutral signal generated by the gear sensor (transmitted to the engine control unit over the can line), the side stand position signal is used to enable or disable engine start.

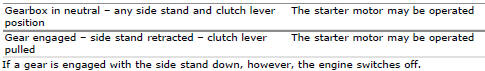

The following table indicates the only conditions in which starter motor

activation and, as a result, engine start, are

permitted:

Component assembling position

The side stand button is integrated in the rotation pivot area of the side stand itself.

location of side stand connection.

Connection wiring diagram

Ccm engine control connection, s side stand button. 3 Black - bk, 2 white/black - w/bk.

In the event of fault

In the event of a side stand button fault, the safety conditions described in the introduction are not met.

Fault codes generated and possible correlated faults

The engine control unit generates no fault code in the event of a side stand button fault.

No errors are indicated on the dashboard.

- Integrity of electric circuit (open circuit, short-circuit to ground and toward vdc) and of the electrical connections

- Integrity of the side stand button. When the side stand is used (extended and retracted), the resistance on the button contacts (pin 2 and pin 3) must be zero in one position (continuity) and infinite in the other (open circuit)

Note

Check integrity of electric circuit - short-circuit to vdc = with dashboard on, using a voltmeter, a voltage is measured between the wire tested and ground.

Check integrity of electric circuit - short-circuit to ground = with the battery cables disconnected, using an ohmmeter, continuity is detected between the wire tested and ground.

Check integrity of electric circuit - open circuit = with the battery cables disconnected, using an ohmmeter, no continuity is detected between the two ends of the wire tested.

The dds instrument can be used to display the activation state of the side stand button.

If none of the aforementioned tests identify the problem and the side stand button is in proper working order, replace the engine control unit.

Component replacement methods

No special measures are necessary in order to replace the side stand button.

Clutch lever button

Clutch lever button

Introduction

The clutch button is located on the clutch lever. Together with the signal

from the side stand button and the neutral signal

generated by the gear sensor (transmitted to the engine co ...

Injection relay

Injection relay

Introduction

The fuel pump, injectors and ignition coils are all powered via the injection

relay. The relay also sends voltage to the

engine control unit, which enables activation of the relay its ...

Other materials:

Removing the frame and the lateral footrests

Loosen the two special screws (6) to separate the frame (1) from the lateral

brackets (2) and (3).

On the left side of the vehicle block retaining pins (9) and loosen the nuts (8)

on the right side at the same time.

Slide out the retaining pins (9) and remove the frame (1) from the lateral ...

Operations to be carried out by the dealer

List of operations to be performed every 12000 km / year (first

limit reached)

Reading of the error memory with dds on the engine control units,

vehicle and abs

Change the engine oil

Change the engine oil filter

Check and/or adjust valve clearance ( ...

Engine temperature sensor

Introduction

The engine control system on the diavel uses a sensor that measures the

temperature of the coolant (engine

temperature). This sensor has a resistance of ntc type (negative temperature

coefficient), that reduces its own value

when the temperature increases. The engine temperature ...