Ducati Diavel Service Manual: Solenoid starter

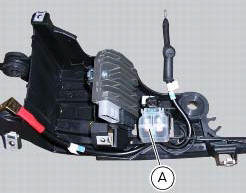

Remove the protection cover (a).

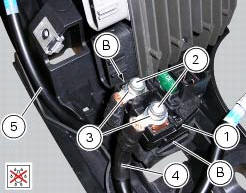

Undo the screws (2), taking care to collect the spring washers (3).

Remove the starter motor-solenoid cable (4) and the solenoid-battery cable (5).

Remove the starter solenoid (1) sliding it upwards.

Checking operation of the starter solenoid

To check the solenoid starter proceed as indicated in sect. 6 - 8, "Starter motor relay".

Ensure that the terminals are not oxidised.

Position the solenoid-starter motor cable (4) and the solenoid-battery cable (5) on the solenoid terminals.

Start the screws (2) fitting the spring washers (3).

Tighten the screws (2) to a torque of 4 nm +/- 10% (sect. 3 - 3, Frame torque settings).

Apply waterproof spray in the area of the screws.

Fix the starter solenoid (1) to the battery support inserting it in the tongues (b).

Refit the protection cover (a) inserting it on the solenoid starter guides until it engages with the tabs on both sides of the solenoid starter.

Starter motor

Starter motor

Power:

0.7 Kw/12 v

Direction of rotation:

counter clockwise viewed from power take-off side.

The starter motor is highly compact and reliable and therefore rarely gives

any type of problem. ...

Other materials:

Vehicle pre-delivery

Transport packaging integrity check (if required);

Removal from the transport packaging (if required);

Motorcycle integrity check;

Check of the supplied kit completeness (refer to the parts list supplied

together with the bike packaging);

Only if the bike is supplied in a crate: handle ...

Removal of the throttle twistgrip

Peel back the rubber sleeve (a) protecting the throttle control cables.

Undo the screws (b) of the throttle grip (6) and open the command.

Disconnect the throttle grip cables (10) by unhooking the cable ends (c) from

their seats.

Remove the throttle twistgrip (6) from the handlebar.

...

Removal of the gear selector lever

Unscrew and remove the fixing screws (18) and (20) of the complete gear

selector lever (21) and collect the spacer (19).

Remove the gearchange mechanism complete with the shaft, spring, and stop plate.

Important

Visually inspect the gear selector claw (14) for wear, particularly aroun ...