Ducati Diavel Service Manual: Spark plugs replacement

Check the colour of the ceramic insulation around the central electrode: an even, light brown colour indicates the engine is in good condition and running at the right temperature.

Inspect the centre electrode for wear and check spark plug gap, which should be: 0.8+/-0.1 Mm.

Important

Check the gap between the central and side electrodes. Replace the spark plug if taken value is different from the specified one or the spark plug shows clear signs of carbon settling.

Important

Do not use spark plugs with inadequate thermal rating or incorrect thread length.

The spark plug must be securely installed.

If a spark plug is loose, it can overheat and damage the engine.

Spark plug type

Make: ngk

Type: mar9a-j

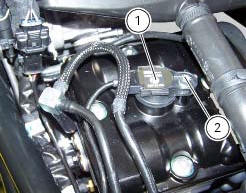

Remove the coil-spark plugs wires (1), loosening the screws (2) of both spark plugs.

Using the appropriate tool 88713.2877 To replace the spark plugs.

Place the coil-spark plugs wires (1) in the relevant seats and tighten the screws (2) to a torque of 10 nm (min. 9 Nm - max. 11 Nm) (sect. 3 - 3, Engine torque settings).

Checking valve clearances

Checking valve clearances

To check the valves clearance, it is necessary to have access to the cylinder

head covers and then remove the

components listed below.

Unscrew the two fixing screws (1) of the cover (2) accord ...

Changing and cleaning the air filters

Changing and cleaning the air filters

The air filter must be replaced at the intervals described in the "scheduled

maintenance chart" (sect. 4 - 2).

Work on the vehicle right side, loosen screws (1) that secure the intake duct

(2 ...

Other materials:

Refitting the rear sprocket

Check the cush drive bushes (6) condition and, if necessary, replace them by

removing them from the flange.

Refitting is the reverse of removal.

Apply recommended grease on the rear sprocket flange (5) external diameter.

Place the rear sprocket flange (5) on sprocket (17) by inserting it ...

Explanation of the function of the ride-by-wire system

Mechanism

Via metal cables, the throttle grip operates a roller mounted on one end of a

spindle located near the horizontal cylinder

throttle valve spindle.

The aps sensor, which measures the position of the throttle grip itself, is

mounted on the opposite end of this spindle.

A mechanic ...

Injection and ignition

Introduction

Ignition is via a single stick coil per cylinder installed in the spark plug

well. Each thermal unit is supplied by a single

injector, placed under the throttle valve. The amount of fuel injected and the

ignition advances are determined by the

control unit specifically for each c ...