Ducati Diavel Service Manual: Starter motor relay

Introduction

When the rider presses the start button, with all the safety conditions required to enable engine start met, the engine control unit enables the relay that activates the starter motor.

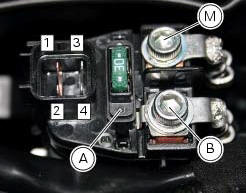

Component assembling position

Connection on starter motor relay.

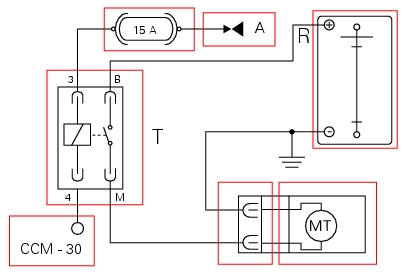

Connection wiring diagram

Mt starter motor, ccm engine control connection. 4 Starter motor relay activation, blue/black - b/bk, a key on power (+15 from hands free relay 30), r battery power (+30), 3 red/black - r/bk, m black - bk, b black - bk.

In the event of fault

In the event of a starter motor relay fault, the engine will not start.

Fault codes generated and possible correlated faults

The engine control unit generates no fault code in the event of a starter motor relay fault.

No errors are indicated on the dashboard.

Possible correlated faults: the starter motor cannot be operated. Check:

- Battery state of charge

- If power supply voltage (12 v - key-on) is present on pin 3 of the starter motor relay (if not, consult the paragraph "hands free") and check the integrity of the 15a fuse

- Integrity of the electrical circuit and electrical connections of the starter motor relay

- Integrity of the starter motor relay. After removing the relay, when 12 v power is applied to pin 3 and pin 4, the contacts should close (continuity between pin b and pin m)

- Integrity of the starter motor and that the motor is correctly connected to the electrical system (also check ground Connection on engine, see sect. 6 - 3"Starter motor")

- The integrity of the engine start button and its circuit

- The integrity of the side stand switch, the clutch lever switch, the gear position sensor and their respective circuits

- Integrity of stop engine switch

Note

Check integrity of electric circuit - short-circuit to vdc = with dashboard on, using a voltmeter, a voltage is measured between the wire tested and ground.

Check integrity of electric circuit - short-circuit to ground = with the battery cables disconnected, using an ohmmeter, continuity is detected between the wire tested and ground.

Check integrity of electric circuit - open circuit = with the battery cables disconnected, using an ohmmeter, no continuity is detected between the two ends of the wire tested.

If none of the tests described above identifies the problem and the power supply and ground for the engine control unit are in correct working order, replace the engine control unit.

Component replacement methods

No special measures are necessary in order to replace the starter motor relay.

Throttle valve actuator motor relay

Throttle valve actuator motor relay

Introduction

The throttle valve actuator motor is powered by the engine control unit. The

engine control unit receives the necessary

power from a specific relay.

Component assembling position

...

Radiator fan relay

Radiator fan relay

Introduction

The radiator fans are powered via a specific relay, which is enabled by the

engine control unit.

Component assembling position

A injection relay; b etv relay (throttle valve actu ...

Other materials:

Low hands free key (hf) battery level

The activation of this (amber yellow) "warning" indicates that the hands free

system has detected that the battery that

permits the active key (a) to communicate and turn the vehicle on is almost

discharged.

Note

In this case replace as soon as possible the battery as indicated in sect.

6 - ...

Indicator trip time - trip time

This function shows the vehicle trip time.

The calculation is made considering the time travelled since

the last trip 1 reset. When trip 1 is reset, the value is set to

zero.

The active phase calculation occurs when the engine is

running and the vehicle is stopped (when the vehicle is not

...

Instrument panel (dashboard)

The vehicle is equipped with two instrument panels: an lcd

(1, fig. 3) Located on the handlebar containing the key

indications (speed, rpm, coolant temperature and clock) and

a tft colour display (2, fig. 3) Located in the tank fairing

displaying trip information (riding style set, odometer,

co ...