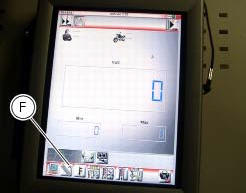

Ducati Diavel Service Manual: Testing the battery charging system

Note

The on-screen icons used during this procedure are explained in a table at the end of this section.

You can determine the engine rpm required for generator to produce just enough current to charge battery, feed the injection ignition system and all electric items fitted to motorcycle. When applied to a cable, the clamp-type amperemeter (1) part no. 88765.1126V detects the magnetic field generated by the current passing through that cable.

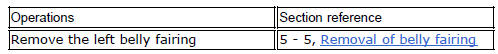

Turn on the dds diagnosis instrument (2) referring to the paragraph "tester power supply".

Connect the power and diagnosis cable (measurement module) (3) part no. 97900.0222 To the measurement module connector (d) of the dds (2).

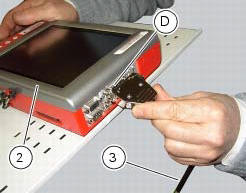

Connect the clamp-type amperemeter (1) to the connector (e) of the power and diagnosis cable (measurement module) (3).

Warning

The clamp-type amperemeter must not be connected to wires through which electrical current is flowing.

Insert the clamp-type amperemeter into the battery positive terminal lead with the arrow on the clamp pointing towards the battery positive terminal (+).

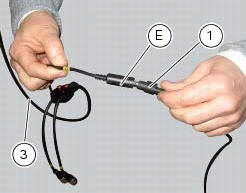

On the dds diagnosis instrument (2), select the "measurement module" function by pressing the corresponding icon; then press the "ammeter" icon (f) followed by the "start" icon.

The socket to which the cable (measurement module) (3) is to be connected is indicated on the screen with a capital letter: a, b or c.

If the measured current is a positive quantity, it means that generator is feeding all electric items and charging battery at the same time. If the current has a negative sign, this means that the charging system is not able to power the electrical loads and a significant amount of the current required must be supplied by the battery, which is therefore discharging.

Important

If polarity is reversed when clamping the ammeter onto the cable, the sign of the readings will also be reversed, giving rise to incorrect diagnosis.

Guided diagnosis

Guided diagnosis

Note

The on-screen icons used during this procedure are explained in a table at

the end of this section.

The dds diagnosis instrument guides the operator step-by-step through the

various diagnos ...

Deactivating the service indication on the dashboard

Deactivating the service indication on the dashboard

The message "serv" is displayed on the dashboard, indicating that the

motorcycle should be serviced in accordance with

the programmed maintenance plan. This indication is activated after the first ...

Other materials:

Removing of the front sprocket

Undo the screws (11) and remove the chain cover (10).

Loosen the chain (sect. 4 - 3, Adjusting the chain tension).

Remove the chain with the tool code 88713.1344.

The tool is composed of a holder (a), punch (b), body (c) and two wrenches (d)

and (e).

Fit the link to be opened into th ...

Dashboard system

The vehicle is equipped with two dashboards: an lcd (1) located on the

handlebar containing the key indications (speed,

rpm, engine coolant temperature, and clock) and a tft colour display (2) located

in the tank fairing displaying trip

information (riding style set, odometer, consumption, ave ...

Pre-ride checks

Warning

failure to carry out these checks before riding, may

lead to motorcycle damage and injury to rider and passenger.

Before riding, perform a thorough check-up on your bike as

follows:

Fuel level in the tank

Check the fuel level in the tank. Fill tank if needed (page 140).

Engine oil le ...