Ducati Diavel Service Manual: Throttle valve operation engine

Introduction

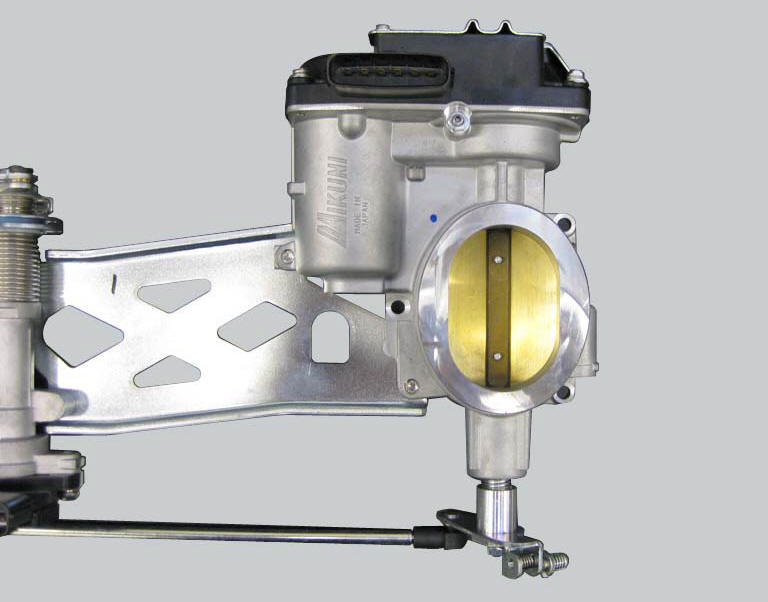

The electric motor actuating the throttle valve for the vertical cylinder is mounted on the throttle body of the diavel, while a link rod connects the vertical cylinder throttle valve to the horizontal cylinder throttle valve. In the electric motor, the throttle valve position sensor (tps) is integrated.

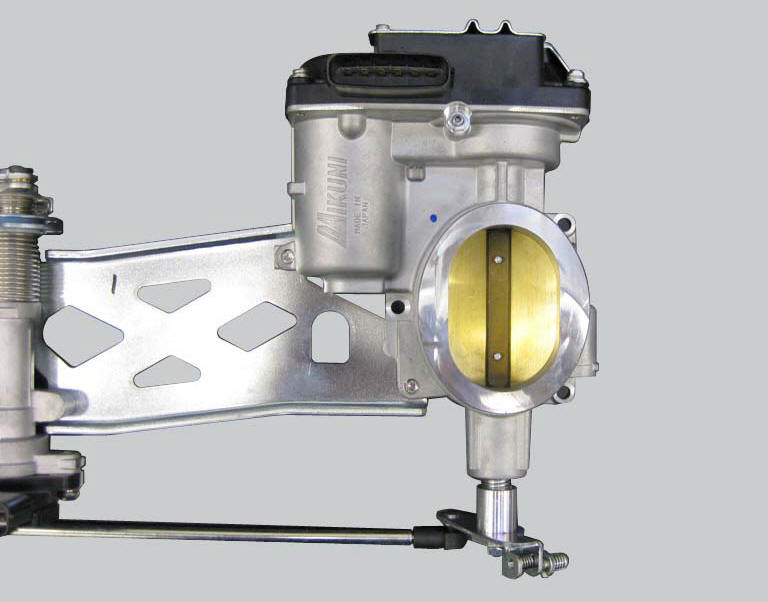

The electric motor, which also incorporates the throttle valve position sensor (tps), is visible on the right, on the throttle body. The accelerator position sensor (aps) is visible on the left.

Component assembling position

The electric motor, which also incorporates the throttle valve position sensor (tps), is visible on the right, on the throttle body. The accelerator position sensor (aps) is visible on the left.

Component assembling position

The image shows the throttle valve actuator motor. Inside of it, it is also placed the throttle valve position sensor (tps).

Location of electric connection for throttle valve actuator motor - tps (throttle valve position sensor).

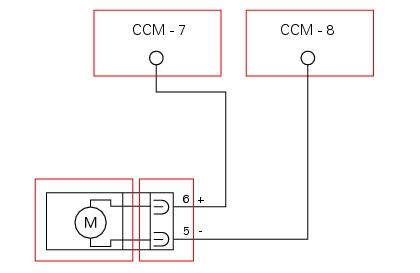

Connection wiring diagram

Ccm engine control connection, m throttle valve actuator motor. 5 Light blue/red - lb/r, 6 light blue/black- lb/bk.

In the event of fault

In the event of a throttle valve actuator fault, motor power is cut off and the throttle valves close (see chapter relative to ride-by-wire system).

Fault codes generated and possible correlated faults fault codes generated by the engine control unit and displayed by the dds (etv motor diagnosis):

- Open circuit (feedback error): check integrity of electric circuit and electrical connections.

- Short circuit to vdc: check integrity of electric circuit and electrical connections.

- Short circuit to ground: check integrity of electric circuit and electrical connections.

Note

Check integrity of electric circuit - short-circuit to vdc = with dashboard on, using a voltmeter, a voltage is measured between the wire tested and ground.

Check integrity of electric circuit - short-circuit to ground = with the battery cables disconnected, using an ohmmeter, continuity is detected between the wire tested and ground.

Check integrity of electric circuit - open circuit = with the battery cables disconnected, using an ohmmeter, no continuity is detected between the two ends of the wire tested.

The dashboard service display shows the error "etv motor" (throttle valve actuator motor) and the eobd warning light activates.

Possible correlated faults: the engine does not start, cuts out or remains running at idle speed and will not accelerate.

Check:

- Functionality of throttle valve actuator motor relay (see paragraph "throttle valve actuator relay")

The throttle valve actuator motor may be actuated into three preset positions (0%, 50%, 100%) using the dds.

If none of the tests described above identify the problem and the throttle valve actuator is in proper working order, contact ducati.

Component replacement methods

The throttle valve actuator motor incorporates the throttle valve position sensor (tps) and cannot be replaced as an individual component. In case it brakes down it will be necessary to fit a new throttle body (refer to sect. 6 - 8, Operating principle and characteristics of the ride-by-wire system). After replacement of the throttle body, reset the self-adaptive parameters relative to carburation with the dds. Adjust the cables connecting the throttle grip to the throttle grip position sensor.

Injectors

Injectors

Introduction

The injectors used on the diavel are top feed units, meaning that fuel is fed

into the top of the injector itself. The

injectors contain a winding which raises a needle when electrica ...

Engine start button

Engine start button

Introduction

The engine start button is located on the right hand handlebar switchgear set

and is used to turn the engine on.

Component assembling position

The engine start button is included ...

Other materials:

Disassembly of the clutch cover

Remove the plug (14) and its o-ring (13), the plug (17) and its o-ring (15)

from the cover.

Undo the fixing screw (16) of the inner cover (19).

Remove the inner cover (6) and soundproofing panel (18).

Remove the circlip (10) and withdraw the shim (9) and the sealing ring (8).

The dri ...

Fuel system circuit

The fuel system circuit consists of:

An electric pump, driven by the injection relay, which is in turn

controlled by the ecu (engine control unit)

A fuel filter

A pressure regulator

Two injectors (one per cylinder, located downstream of throttle valve)

The plastic mounting shown in t ...

Checking protection and safety device components

Checking the side stand switch

Remove the switch (1) from the side stand undoing screw (2) and disconnect

the main wiring connector from the switch

(see paragraph "routing of wiring on frame", sect. 6 - 1).

Use an analogue or digital multimeter (sect. 6 - 11, Using a multimeter to check

the ...