Ducati Diavel Service Manual: Turn indicators not working

Fault codes

Dds: no fault code displayed.

Dashboard: no fault code displayed.

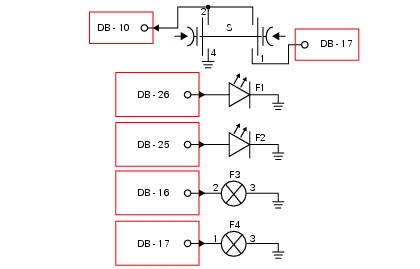

Wiring diagram

Db dashboard connection, bbs bbs unit connection, s turn indicator button, f1 front left turn indicator, f2 front right turn indicator, f3 rear left turn indicator, f4 rear right turn indicator. 2 On grey button - gr, 1 on red/blue button - r/b, 4 on black button - bk, db 26 white/black w/bk, db 25 green/black - g/bk, bbs 16 white/green - w/g, bbs 17 White/black w/bk.

Location of connections and components

Location of rear turn indicator and number plate light connection.

Location of left hand handlebar switchgear set connection.

Location of front right turn indicator connection.

Location of front left turn indicator connection.

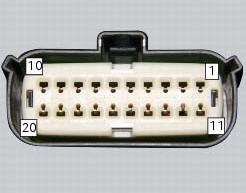

Pin numbering for wiring harness side dashboard connector.

Pin numbering of wiring harness side bbs unit connection.

Horn not working

Horn not working

Fault codes

Dds: horn diagnosis -> short circuit to ground (s.C. Gnd).

Dashboard: the error "claxon" (horn) is shown on the service display. The eobd

warning light activates.

Wiring diagram

...

High beam flash not working - start/stop lap function not working

High beam flash not working - start/stop lap function not working

Fault codes

Dds: no fault code displayed.

Dashboard: no fault code displayed.

Wiring diagram

Db dashboard connection, s high beam flash button. 7 Orange - o, 1

red/blue - r/b.

Location of ...

Other materials:

Refitting the rear suspension

Lubricate the thread and underside of the special screw (1).

Insert the lower side of the shock absorber into the swingarm and insert the

screw (1).

Tighten the screw (1) to a torque of 45 nm +/- 5% (sect. 3 - 3, Frame torque

settings).

Lubricate bushes (5) and (6) with recommended gr ...

Refitting the filler cap

Position seal (18) in tank cap (10) as shown and reassemble following the

removal procedure in the reverse sequence.

In particular tighten the screws (17) to a torque of 3 nm +/- 10% (sect. 3 - 3,

Frame torque settings).

...

Throttle valve actuator motor relay

Introduction

The throttle valve actuator motor is powered by the engine control unit. The

engine control unit receives the necessary

power from a specific relay.

Component assembling position

A injection relay; b etv relay (throttle valve actuator motor), c radiator

fan relay, d engine c ...